KNOTS, SPLICES and ROPE WORK

Giving complete and simple directions for

making all the most useful and ornamental knots in common use, with

tutorials on splicing, pointing, seizing, serving, etc. adapted for the

use of travellers, campers, yachtsmen, boy scouts, and all others having

to use or handle ropes for any purpose.

|

Kinds of Rope. Construction of Rope. Strength of Ropes. Weight of Ropes. Material Used in Making Ropes. Rope Making Machines.

Parts of Rope. Whipping and Seizing Rope. Loops. Cuckolds' Necks.

Clinches. Overhand and Figure-eight Knots. Square and Reef Knots.

Granny Knots. Open-hand and Fishermen's Knots. Ordinary Knots and

Weavers' Knots. Garrick Bends and Hawser Hitches. Half-hitches.

Larks' Heads. Slippery and Half-hitches. Clove Hitches. Gunners' Knots

and Timber Hitches. Twists, Catspaws, and Blackwall Hitches. Chain

Hitch. Rolling and Magnus Hitches. Studding-sail and Gaff-topsail

Halyard Bends. Roband and Fisherman's Hitches.

Waterman's Knot. Larks' Heads with Nooses. Cleat and Wharf Ties.

Bow-line Knots. Loops and Loop Knots.

Two-, Three-, and Fivefold Shortenings. Single Plaits and Monkey

Chain. Twist Braids and Braiding Leather. Open Chains. Seized and Bow

Shortenings. Sheepshanks and Dogshanks. Grommets. Selvagee Straps and

Selvagee Boards. Flemish and Artificial Eyes. Throat Seizings. Lashed Splices.

Wedding Knots and Rose Lashings. Deadeye and Loop Lashings.

Belaying-pin Splice. Necklace Ties. Close Bands and End Pointing.

Ending Ropes. Short Splices. Long Splices. Eye and Cut Splices.

Single Crown Knots. Tucked Crowns. Single Wall Knots. Common and

French Shroud Knots. Double Crown and Double Wall Knots. Crowning Wall

Knots. Double Wall and Crown. Manrope Knots. Topsail-halyard Toggles.

Matthew Walker and Stopper Knots. Turks' Heads and Turks' Caps.

Worming, Parcelling, and Serving. Serving Mallet. Half-hitch Work.

Four-strand and Crown Braids. Rope Buckles and Swivels. Slinging Casks

and Barrels. Rope Belting.

CORDAGE

Before taking up the matter of knots and splices in detail it may be

well to give attention to cordage in general. Cordage, in its broadest

sense, includes all forms and kinds of rope, string, twine, cable,

etc., formed of braided or twisted strands.

In making a rope or line

the fibres (A, Fig. 1) of hemp, jute, cotton, or other material are

loosely twisted together to form what is technically known as a "yarn"

(B, Fig. 1). When two or more yarns are twisted together they form a

"strand" (C, Fig. 1). Three or more strands form a rope (D, Fig.

1), and three ropes form a cable (E, Fig. 1). To form a strand the

yarns are twisted together in the opposite direction from that in

which the original fibres were twisted; to form a rope the strands are

twisted in the opposite direction from the yarns of the strands, and

to form a cable each rope is twisted opposite from the twist of the

strands. In this way the natural tendency for each yarn, strand, or

rope to untwist serves to bind or hold the whole firmly together (Fig. 1).

|

The first rope machine patent was issued to Sellers & Bantle

on May 5, 1807. The Lewis & Clark expedition of 1804 carried a rope

machine on the trip to make rope from animal hides. The machine

was reputed to be a three strand machine with sun and planet gearing,

possibly a Sellers and Bantle machine.

Orson Bucklin of Marietta, Minnesota, patented the rope making

machine shown at the left on November 12, 1901. Three strand hooks

driven by a central gear with an open metal structure, unit mounted onto

an inch thick fence or wagon board. These were a very popular item,

some are still around today.

|

Rope is usually three-stranded and the strands turn from left to right

or "with the sun," while cable is left-handed or twisted "against the

sun" (E, Fig. 1). Certain ropes, such as "bolt-rope" and most

cables, are laid around a "core" (F, Fig. 2) or central strand and

in many cases are four-stranded (Fig. 2).

The strength of a rope depends largely upon the strength and length of

the fibres from which it is made, but the amount each yarn and strand

is twisted, as well as the method used in bleaching or preparing the

fibres, has much to do with the strength of the finished line.

Roughly, the strength of ropes may be calculated by multiplying the

circumference of the rope in inches by itself and the fifth part of

the product will be the number of tons the rope will sustain. For

example, if the rope is 5 inches in circumference, 5 X 5 = 25,

one-fifth of which is 5, the number of tons that can safely be carried

on a 5-inch rope. To ascertain the weight of ordinary "right hand"

rope, multiply the circumference in inches by itself and multiply, the

result by the length of rope in fathoms and divide the product by

3.75. For example, to find the weight of a 5-inch rope, 50 fathoms in

length: 5 X 5 = 25; 25 x 50 = 1,250; 1,250 ÷ 3.75 = 333-1/3 lbs. These

figures apply to Manila or hemp rope, which is the kind commonly used,

but jute, sisal-flax, grass, and silk are also used considerably.

Cotton rope is seldom used save for small hand-lines, clothes-lines,

twine, etc., while wire rope is largely used nowadays for rigging

vessels, derricks, winches, etc., but as splicing wire rope is

different from the method employed in fibre rope, and as knots have no

place in wire rigging, we will not consider it.

|

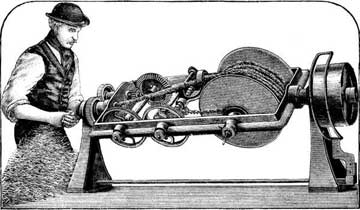

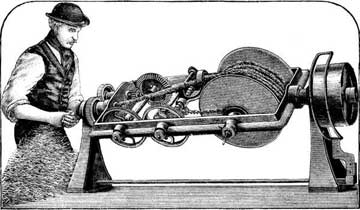

Hay Rope Machine

Machine introduced in 1884 to make rope from hay, the product

was used for many purposes, the principal use was in the foundry for

core-making; but they also found a large application for packing

ironmongery and furniture. The inventor was James Pollard, of the Atlas

Foundry, Burnley.

|