|

Turning and Boring on a Lathe

Online Reprint Chapter 6

This a complete book, published in

1914, divided into chapters on how to use a metal lathe, covering all

turning and boring operations.

|

Return to Contents

Turning and Boring

by Franklin D. Jones

Published by Industrial Press 1914

A special treatise for machinists students in industrial and

engineering schools, and apprentices on turning and boring methods

including modern practice with engine lathes, vertical, and horizontal

boring machines.

Shop Amazon.com

|

CHAPTER VI

VERTICAL BORING MILL PRACTICE

All the different types of turning machines now in use originated

from the lathe. Many of these tools, however, do not resemble the lathe

because, in the process of evolution, there have been many changes made

in order to develop turning machines for handling certain classes of

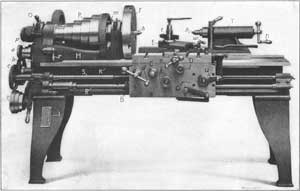

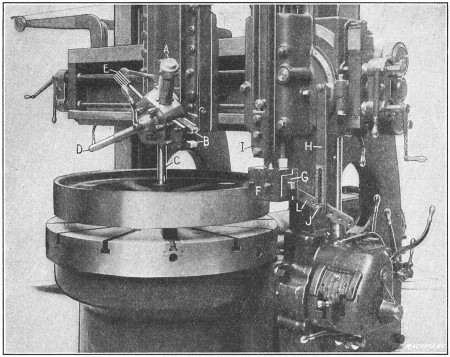

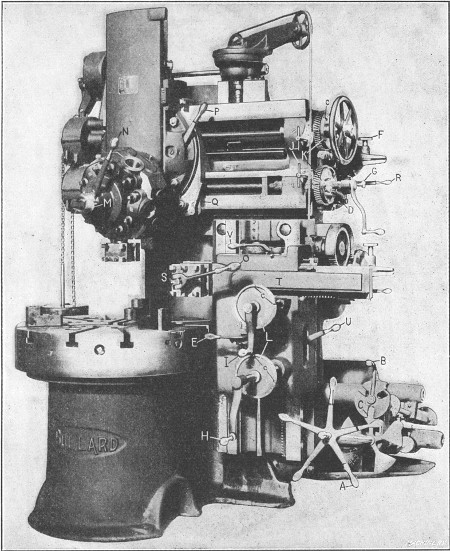

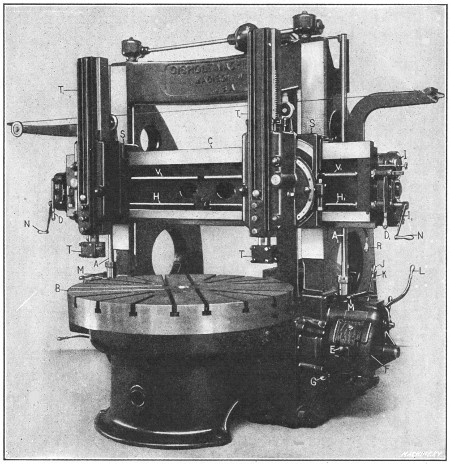

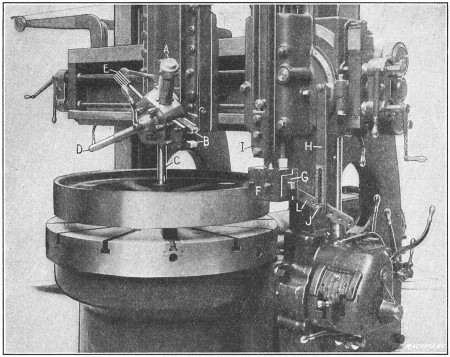

work to the best advantage. The machine illustrated in Fig. 1

belongs to the lathe family and is known as a vertical boring and

turning mill. This type, as the name implies, is used for boring and

turning operations, and it is very efficient for work within its range.

The part to be machined is held to the table B either by clamps

or in chuck jaws attached to the table. When the machine is in

operation, the table revolves and the turning or boring tools (which are

held in tool-blocks T) remain stationary, except for the feeding

movement. Very often more than one tool is used at a time, as will be

shown later by examples of vertical boring mill work. The tool-blocks T are inserted in tool-bars T1 carried by saddles S which are mounted on cross-rail C. Each tool-head (consisting of a saddle and tool-bar) can be moved horizontally along cross-rail C, and the tool-bars T1 have a vertical movement. These movements can be effected either by hand or power.

Fig. 1. Gisholt Vertical Boring and Turning Mill

When a surface is being turned parallel to the work table, the

entire tool-head moves horizontally along the cross-rail, but when a

cylindrical surface is being turned, the tool-bar moves vertically. The

tool-heads are moved horizontally by the screws H and H1, and the vertical feed for the tool-bars is obtained from the splined shafts V and V1,

there being a separate screw and shaft for each head so that the

feeding movements are independent. These feed shafts are rotated for the

power feed by vertical shafts A and A1 on each

side of the machine. These vertical shafts connect with the feed shafts

through bevel and spur gears located at the ends of the cross-rail. On

most boring mills, connection is made with one of the splined shafts V or screw H,

by a movable gear, which is placed on whichever shaft will give the

desired direction of feed. The particular machine illustrated is so

arranged that either the right or left screw or feed shaft can be

engaged by simply shifting levers D1 or D.

The amount of feed per revolution of the table is varied for each tool-head by feed-changing mechanisms F

on each side of the machine. These feed boxes contain gears of

different sizes, and by changing the combinations of these gears, the

amount of feed is varied. Five feed changes are obtained on this machine

by shifting lever E, and this number is doubled by shifting lever G.

By having two feed boxes, the feeding movement of each head can be

varied independently. The direction of either the horizontal or vertical

feed can be reversed by lever R, which is also used for engaging or disengaging the feeds. This machine is equipped with the dials I and I1

which can be set to automatically disengage the feed at any

predetermined point. There are also micrometer dials graduated to

thousandths of an inch and used for adjusting the tools without the use

of measuring instruments.

The work table B is driven indirectly from a belt pulley at

the rear, which transmits the power through gearing. The speed of the

table can be varied for turning large or small parts, by levers J and K and the table can be started, stopped or rotated part of a revolution by lever L

which connects with a friction clutch. There are corresponding feed and

speed levers on the opposite side, so that the machine can be

controlled from either position.

The heads can be adjusted along the cross-rail for setting the tools by hand-cranks N, and the tool slides can be moved vertically by turning shafts V

with the same cranks. With this machine, however, these adjustments do

not have to be made by hand, ordinarily, as there are rapid power

movements controlled by levers M. These levers automatically

disengage the feeds and enable the tool-heads to be rapidly shifted to

the required position, the direction of the movement depending upon the

position of the feed reverse lever R and lever D. This

rapid traverse, which is a feature applied to modern boring mills of

medium and large size, saves time and the labor connected with hand

adjustments. The cross-rail C has a vertical adjustment on the

faces of the right and left housings which support it, in order to

locate the tool-heads at the right height for the work. This adjustment

is effected by power and is controlled by levers at the sides of the

housings. Normally, the cross-rail is bolted to the housings, and these

bolts must be loosened before making the adjustment, and must always be

tightened afterwards.

The function of these different levers has been explained to show,

in a general way, how a vertical boring machine is operated. It should

be understood, however, that the arrangement differs considerably on

machines of other makes. The construction also varies considerably on

machines of the same make but of different size.

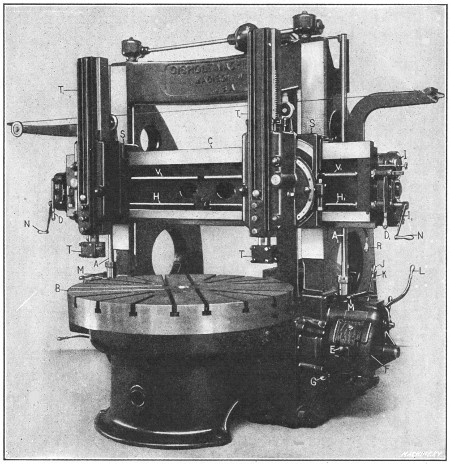

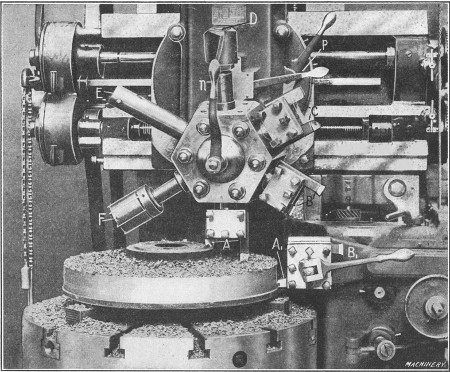

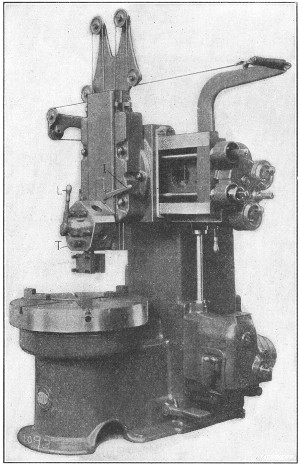

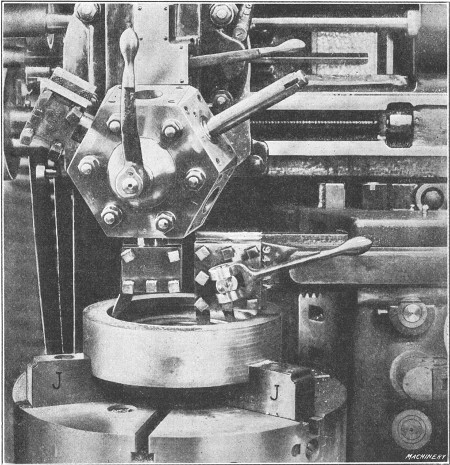

Fig. 2. Small Boring and Turning Mill

with Single Turret-head

All modern vertical boring mills of medium and large sizes are equipped with two tool-heads, as shown in Fig. 1,

because a great deal of work done on a machine of this type can have

two surfaces machined simultaneously. On the other hand, small mills of

the type illustrated in Fig. 2 have a single head. The toolslide of this machine, instead of having a single tool-block, carries a five-sided turret T

in which different tools can be mounted. These tools are shifted to the

working position as they are needed, by loosening binder lever L and turning or “indexing” the turret. The turret is located and locked in any of its five positions by lever I,

which controls a plunger that engages notches at the rear. Frequently,

all the tools for machining a part can be held in the turret, so that

little time is required for changing from one tool to the next. Some

large machines having two tool-heads are also equipped with a turret on

one head.

Boring and Turning in a Vertical Boring Mill.—The vertical

boring mill is, in many respects, like a lathe placed in a vertical

position, the table of the mill corresponding to the faceplate or chuck

of the lathe and the tool-head to the lathe carriage. Much of the work

done by a vertical mill could also be machined in a lathe, but the

former is much more efficient for work within its range. To begin with,

it is more convenient to clamp work to a horizontal table than to the

vertical surface of a lathe faceplate, or, as someone has aptly said,

“It is easier to lay a piece down than to hang it up.” This is

especially true of the heavy parts for which the boring mill is

principally used. Very deep roughing cuts can also be taken with a

vertical mill. This type of machine mill is designed for turning and

boring work which, generally speaking, is quite large in diameter in

proportion to the width or height. The work varies greatly, especially

in regard to its diameter, so that boring mills are built in a large

range of sizes. The small and medium sizes will swing work varying from

about 30 inches to 6 or 7 feet in diameter, whereas large machines, such

as are used for turning very large flywheels, sheaves, etc., have a

swing of 16 or 20 feet, and larger sizes are used in some shops. The

size of a vertical mill, like any other machine tool, should be somewhat

in proportion to the size of the work for which it is intended, as a

very large machine is unwieldy, and, therefore, inefficient for

machining comparatively small parts.

Holding and Setting Work on Boring Mill Table.—There

are three general methods of holding work to the table of a boring

mill; namely, by the use of chucks, by ordinary bolts and clamps, or in

special fixtures. Chucks which are built into the table (as illustrated

in Fig. 2) and have both universal and

independent adjustments for the jaws can be used to advantage for

holding castings that are either round or irregular in shape. The

universal adjustment is used for cylindrical parts, such as disks,

flywheels, gear blanks, etc., and the independent adjustment, for

castings of irregular shape. Chucks which have either an independent or

universal movement for the jaws are known as a “combination” type and

usually have three jaws. There is also a four-jaw type which has the

independent adjustment only. This style is preferable for work that is

not cylindrical and which must be held very securely. Chuck jaws that do

not form a part of the machine table, but are bolted to it in the

required position, are also employed extensively, especially on

comparatively large machines.

Most of the work done in a vertical mill is held in a chuck.

Occasionally, however, it is preferable to clamp a part directly to the

table. This may be desirable because of the shape and size of the work,

or because it is necessary to hold a previously machined surface

directly against the table in order to secure greater accuracy.

Sometimes a casting is held in the chuck for turning one side, and then

the finished side is clamped against the table for turning the opposite

side. Parts which are to be machined in large quantities are often held

in special fixtures. This method is employed when it enables the work to

be set up more quickly than would be possible if regular clamps or

chuck jaws were used.

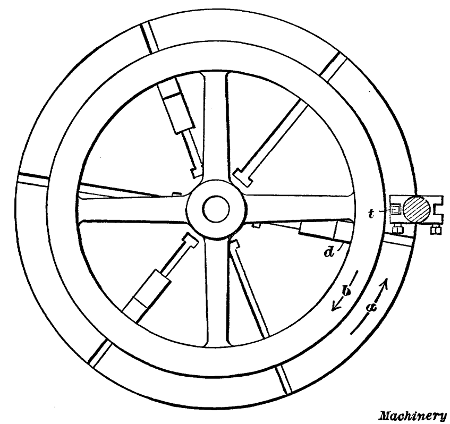

Fig. 3. Plan View showing Flywheel Casting Chucked for Turning

Work that is to be turned or bored should first be set so that the

part to be machined is about central with the table. For example, the

rim of a flywheel should be set to run true so that it can be finished

by removing about the same amount of metal around the entire rim; in

other words, the rim should be set concentric with the table, as shown

in Fig. 3, and the sides of the rim should also be parallel to the table.

A simple tool that is very useful for testing the position of any

cylindrical casting consists of a wooden shank into which is inserted a

piece of wire, having one end bent. This tool is clamped in the toolpost

and as the work revolves the wire is adjusted close to the cylindrical

surface being tested. The movement of the work with relation to the

stationary wire point will, of course, show whether or not the part runs

true. The advantage of using a piece of wire for testing, instead of a

rigid tool, is that the wire, owing to its flexibility, will simply be

bent backward if it is moved too close to a surface which is

considerably out of true. The upper surface of a casting can be tested

for parallelism with the table by using this same wire gage, or by

comparing the surface, as the table is revolved slowly, with a tool held

in the toolpost. An ordinary surface gage is also used for this

purpose. The proper surface to set true, in any case, depends upon the

requirements. A plain cylindrical disk would be set so that the outside

ran true and the top surface was parallel with the table. When setting a

flywheel, if the inside of the rim is to remain rough, the casting

should be set by this surface rather than by the outside, so that the

rim, when finished, will be uniform in thickness.

As far as possible, chucks should be used for holding cylindrical

parts, owing to their convenience. The jaws should be set against an

interior cylindrical surface whenever this is feasible. To illustrate,

the flywheel in Fig. 3 is gripped by the inside

of the rim which permits the outside to be turned at this setting of the

work. It is also advisable to set a flywheel casting in the chuck so

that a spoke rests against one of the jaws as at d, if this is

possible. This jaw will then act as a driver and prevent the casting

from slipping or turning in the chuck jaws, owing to the tangential

pressure of the turning tool. When a cut is being taken, the table and

work rotate as shown by arrow a, and the thrust of the cut (taken by tool t) tends to move the wheel backward against the direction of rotation, as shown by arrow b.

If one of the chuck jaws bears against one of the spokes, this movement

is prevented. It is not always feasible to use a chuck jaw as a driver

and then a special driver having the form of a small angle-plate or

block is sometimes bolted directly to the table. Another method of

driving is to set a brace between a spoke or projection on the work and a

chuck jaw or strip attached to the table. Drivers are not only used

when turning flywheels, but in connection with any large casting,

especially when heavy cuts have to be taken. Of course, some castings

are so shaped that drivers cannot be employed.

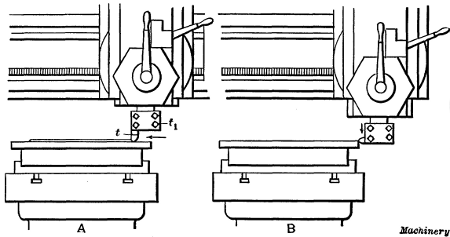

Fig. 4. (A) Turning a Flat Surface.

(B) Turning a Cylindrical Surface

Turning in a Boring Mill.—The vertical type of boring mill

is used more for turning cylindrical surfaces than for actual boring,

although a large part of the work requires both turning and boring. We

shall first consider, in a general way, how surfaces are turned and then

refer to some boring operations. The diagram A, Fig. 4, illustrates how a horizontal surface would be turned. The tool t is clamped in tool-block t1,

in a vertical position, and it is fed horizontally as the table and

work rotate. The tool is first adjusted by hand for the proper depth of

cut and the automatic horizontal feed is then engaged. When a

cylindrical surface is to be turned, the tool (provided a straight tool

is used) is clamped in a horizontal position and is fed downward as

indicated at B. The amount that the tool should feed per

revolution of the work, depends upon the kind of material being turned,

the diameter of the turned part and the depth of the cut.

Most of the parts machined in a vertical boring mill are made of

cast iron and, ordinarily, at least one roughing and one finishing cut

is taken. The number of roughing cuts required in any case depends, of

course, upon the amount of metal to be removed. An ordinary roughing cut

in soft cast iron might vary in depth from 1/8 or 3/16 inch to 3/8 or 1/2 inch and the tool would probably have a feed per revolution of from 1/16 to 1/8

inch, although deeper cuts and coarser feeds are sometimes taken. These

figures are merely given to show, in a general way, what cuts and feeds

are practicable. The tool used for roughing usually has a rounded end

which leaves a ridged or rough surface. To obtain a smooth finish, broad

flat tools are used. The flat cutting edge is set parallel to the

tool's travel and a coarse feed is used in order to reduce the time

required for taking the cut. The finishing feeds for cast iron vary from

1/4 to 3/4 inch on ordinary work. The different tools used on the vertical mill will be referred to more in detail later.

All medium and large sized vertical boring mills are equipped with

two tool-heads and two tools are frequently used at the same time,

especially on large work. Fig. 9 illustrates the

use of two tools simultaneously. The casting shown is a flywheel, and

the tool on the right side turns the upper side of the rim, while the

tool on the left side turns the outside or cylindrical surface. As a

boring mill table rotates in a counter-clockwise direction, the

left-hand tool is reversed to bring the cutting edge at the rear. By

turning two surfaces at once, the total time for machining the casting

is, of course, greatly reduced. The turning of flywheels is a common

vertical boring mill operation, and this work will be referred to in

detail later on.

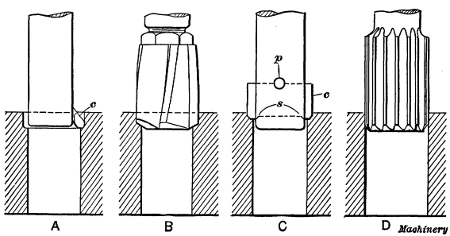

Fig. 5. Tools for Boring and Reaming Holes

Boring Operations.—There are several methods of machining

holes when using a vertical boring mill. Ordinarily, small holes are

cored in castings and it is simply necessary to finish the rough surface

to the required diameter. Some of the tools used for boring and

finishing comparatively small holes are shown in Fig. 5. Sketch A shows a boring tool consisting of a cutter c

inserted in a shank, which, in turn, is held in the tool slide, or in a

turret attached to the tool slide. With a tool of this type, a hole is

bored by taking one or more cuts down through it. The tool shown at B

is a four-lipped drill which is used for drilling cored holes

preparatory to finishing by a cutter or reamer. This drill would

probably finish a hole to within about 1/32 inch of the finish diameter, thus leaving a small amount of metal for the reamer to remove. The tool illustrated at C has a double-ended flat cutter c,

which cuts on both sides. These cutters are often made in sets for

boring duplicate parts. Ordinarily, there are two cutters in a set, one

being used for roughing and the other for finishing. The cutter passes

through a rectangular slot in the bar and this particular style is

centrally located by shoulders s, and is held by a taper pin p.

Some cutter bars have an extension end, or “pilot” as it is called,

which passes through a close-fitting bushing in the table to steady the

bar. Sketch D shows a finishing reamer. This tool takes a very

light cut and is intended to finish holes that have been previously

bored close to the required size. Sometimes a flat cutter C is

used for roughing and a reamer for finishing. The reamer is especially

desirable for interchangeable work, when all holes must have a smooth

finish and be of the same diameter. When a reamer is held rigidly to a

turret or toolslide, it is liable to produce a hole that is either

tapering or larger than the reamer diameter. To prevent this, the reamer

should be held in a “floating” holder which, by means of a slight

adjustment, allows the reamer to align itself with the hole. There are

several methods of securing this “floating” movement. (See “Floating Reamer Holders.”)

Fig. 6. Boring with Regular Turning Tools

Large holes or interior cylindrical surfaces are bored by tools

held in the regular tool-head. The tool is sometimes clamped in a

horizontal position as shown at A, Fig. 6, or a bent type is used as at B. Cast iron is usually finished by a broad flat tool as at C,

the same as when turning exterior surfaces. Obviously a hole that is

bored in this way must be large enough to admit the tool-block.

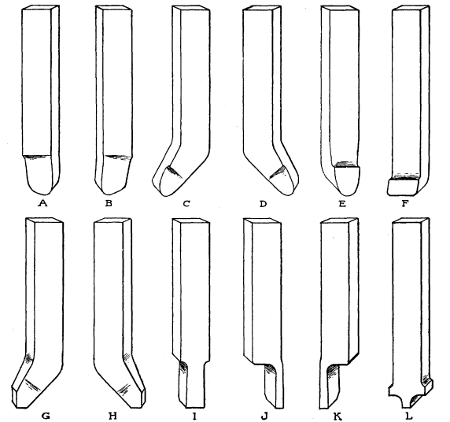

Fig. 7. Set of Boring Mill Tools

Turning Tools for the Vertical Boring Mill.—A set of turning tools for the vertical boring mill is shown in Fig. 7.

These tools can be used for a wide variety of ordinary turning

operations. When a great many duplicate parts are to be machined,

special tool equipment can often be used to advantage, but as the form

of this equipment depends upon the character of the work, only standard

tools have been shown in this illustration. The tool shown at A is a right-hand, roughing tool, and a left-hand tool of the same type is shown at B. Tool C is an offset or bent, left-hand round nose for roughing, and D is a right-hand offset roughing tool. A straight round nose is shown at E. Tool F has a flat, broad cutting edge and is used for finishing. Left-and right-hand finishing tools of the offset type are shown at G and H, respectively. Tool I has a square end and is used for cutting grooves. Right-and left-hand parting tools are shown at J and K, and tool L is a form frequently used for rounding corners.

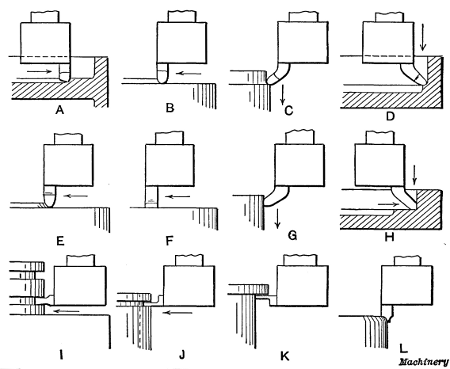

Fig. 8. Diagrams Illustrating Use of Different Forms of Tools

The diagrams in Fig. 8 show, in a general way, how each of the tools illustrated in Fig. 7

are used, and corresponding tools are marked by the same reference

letters in both of these illustrations. The right-and left-hand roughing

tools A and B are especially adapted for taking deep

roughing cuts. One feeds away from the center of the table, or to the

right (when held in the right-hand tool-block) and the other tool is

ground to feed in the opposite direction. Ordinarily, when turning plain

flat surfaces, the cut is started at the outside and the tool feeds

toward the center, as at B, although it is sometimes more convenient to feed in the opposite direction, as at A, especially when there is a rim or other projecting part at the outside edge. The tool shown at A

could also be used for turning cylindrical surfaces, by clamping it in a

horizontal position across the bottom of the tool-block. The feeding

movement would then be downward or at right-angles to the work table.

The offset round-nose tools C and D are for turning

exterior or interior cylinder surfaces. The shank of this tool is

clamped in the tool-block in a vertical position and as the bent end

extends below the tool-block, it can be fed down close to a shoulder.

The straight type shown at E is commonly used for turning steel

or iron, and when the point is drawn out narrower, it is also used for

brass, although the front is then ground without slope. Tool F is

for light finishing cuts and broad feeds. The amount of feed per

revolution of the work should always be less than the width of the

cutting edge as otherwise ridges will be left on the turned surface. The

offset tools G and H are for finishing exterior and

interior cylindrical surfaces. These tools also have both vertical and

horizontal cutting edges and are sometimes used for first finishing a

cylindrical and then a horizontal surface, or vice versa. Tool I

is adapted to such work as cutting packing-ring grooves in engine

pistons, forming square or rectangular grooves, and similar work. The

parting tools J and K can also be used for forming narrow grooves or for cutting off rings, etc. The sketch K (Fig. 8) indicates how a tool of this kind might be used for squaring a corner under a shoulder. Tool L

is frequently used on boring mills for rounding the corners of flywheel

rims, in order to give them a more finished appearance. It has two

cutting edges so that either side can be used as when rounding the inner

and outer corners of a rim.

The turning tools of a vertical boring mill are similar, in many

respects, to those used in a lathe, although the shanks of the former

are shorter and more stocky than those of lathe tools. The cutting edges

of some of the tools also differ somewhat in form, but the principles

which govern the grinding of lathe and boring mill tools are identical,

and those who are not familiar with tool grinding are referred to Chapter II, in which this subject is treated.

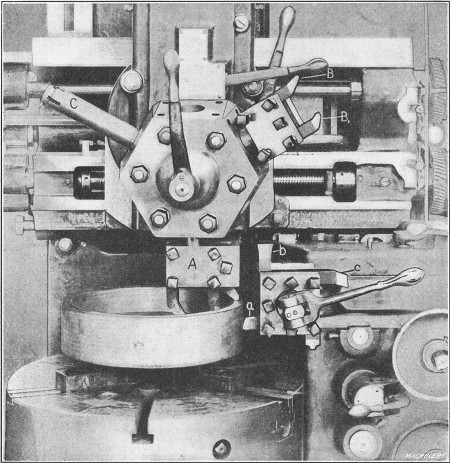

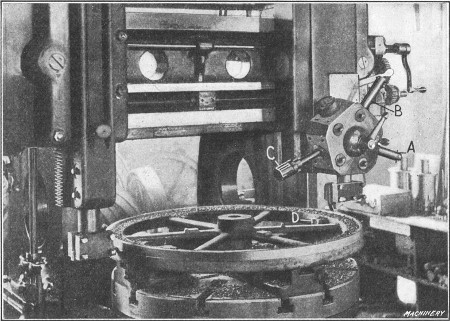

Fig. 9. Turning the Rim of a Flywheel

Turning a Flywheel on a Vertical Mill.—The turning of a

flywheel is a good example of the kind of work for which a vertical

boring mill is adapted. A flywheel should preferably be machined on a

double-head mill so that one side and the periphery of the rim can be

turned at the same time. A common method of holding a flywheel is shown

in Fig. 9. The rim is gripped by four chuck jaws D

which, if practicable, should be on the inside where they will not

interfere with the movement of the tool. Two of the jaws, in this case,

are set against the spokes on opposite sides of the wheel, to act as

drivers and prevent any backward shifting of work when a heavy cut is

being taken. The illustration shows the tool to the right rough turning

the side of the rim, while the left-hand tool turns the periphery.

Finishing cuts are also taken over the rim, at this setting, and the hub

is turned on the outside, faced on top, and the hole bored.

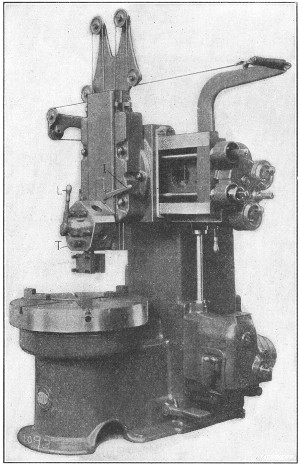

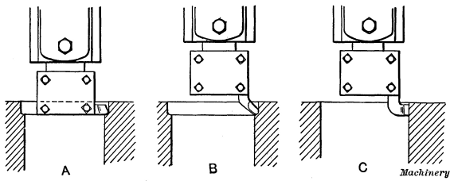

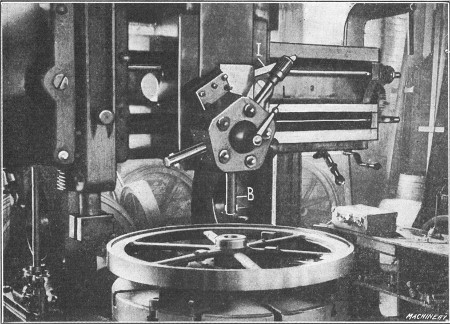

Fig. 10. Tool B set for Boring the Hub

The three tools A, B and C, for finishing the hole, are mounted in the turret. Bar A, which carries a cutter at its end, first rough bores the hole. The sizing cutter B is then used to straighten it before inserting the finishing reamer C. Fig. 10 shows the turret moved over to a central position and the sizing cutter B

set for boring. The head is centrally located (on this particular

machine) by a positive center-stop. The turret is indexed for bringing

the different tools into the working position, by loosening the clamping

lever L and pulling down lever I which disengages the

turret lock-pin. When all the flywheels in a lot have been machined as

described, the opposite side is finished.

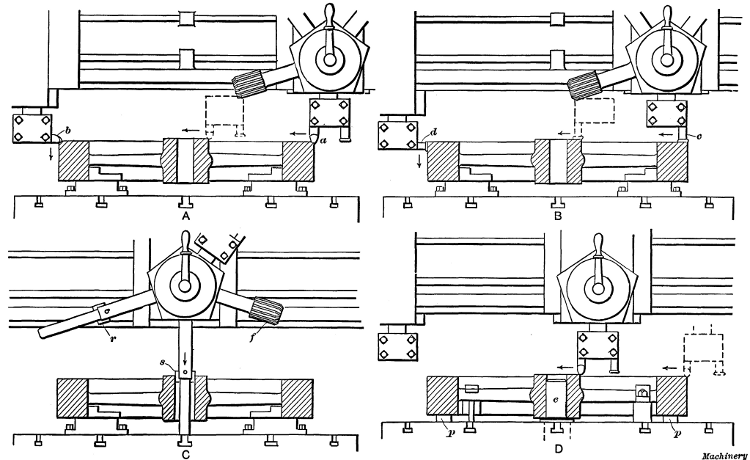

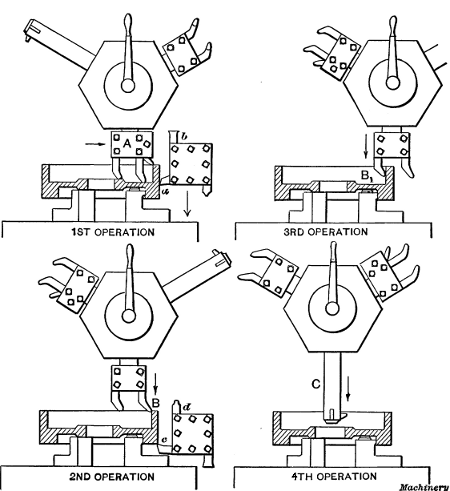

Fig. 11. Diagrams showing Method of Turning and Boring a Flywheel on a Double-head Mill having one Turret Head

In order to show more clearly the method of handling work of this

class, the machining of a flywheel will be explained more in detail in

connection with Fig. 11, which illustrates practically the same equipment as is shown in Figs. 9 and 10. The successive order in which the various operations are performed is as follows: Tool a (see sketch A) rough turns the side of the rim, while tool b,

which is set with its cutting edge toward the rear, rough turns the

outside. The direction of the feeding movement for each tool is

indicated by the arrows. When tool a has crossed the rim, it is

moved over for facing the hub, as shown by the dotted lines. The side

and periphery of the rim are next finished by the broad-nose finishing

tools c and d (see sketch B). The feed should be increased for finishing, so that each tool will have a movement of say 1/4 or 3/8

inch per revolution of the work, and the cuts should, at least, be deep

enough to remove the marks made by the roughing tools. Tool c is

also used for finishing the hub as indicated by the dotted lines. After

these cuts are taken, the outside of the hub and inner surface of the

rim are usually turned down as far as the spokes, by using offset tools

similar to the ones shown at C and D in Fig. 7. The corners of the rim and hub are also rounded to give the work a more finished appearance, by using a tool L.

The next operation is that of finishing the hole through the hub. The hard scale is first removed by a roughing cutter r (sketch C), which is followed by a “sizing” cutter s. The hole is then finished smooth and to the right diameter by reamer f. The bars carrying cutters r and s

have extensions or “pilots” which enter a close-fitting bushing in the

table, in order to steady the bar and hold it in alignment.

When the hole is finished, the wheel is turned over, so that the

lower side of the rim and hub can be faced. The method of holding the

casting for the final operation is shown at D. The chuck jaws are removed, and the finished side of the rim is clamped against parallels p resting on the table. The wheel is centrally located for turning this side by a plug e

which is inserted in a hole in the table and fits the bore of the hub.

The wheel is held by clamps which bear against the spokes. Roughing and

finishing cuts are next taken over the top surface of the rim and hub

and the corners are rounded, which completes the machining operations.

If the rim needs to be a certain width, about the same amount of metal

should be removed from each side, unless sandy spots or “blow-holes” in

the casting make it necessary to take more from one side than from the

other. That side of the rim which was up in the mold when the casting

was made should be turned first, because the porous, spongy spots

usually form on the “cope” or top side of a casting.

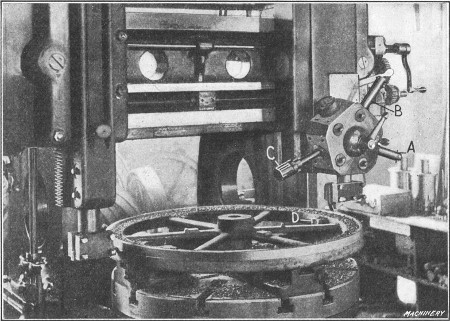

Fig. 12. Gisholt Mill equipped with Convex Turning Attachment

Convex Turning Attachment for Boring Mills.—Fig. 12

shows a vertical boring mill arranged for turning pulleys having convex

rims; that is, the rim, instead of being cylindrical, is rounded

somewhat so that it slopes from the center toward either side. (The

reason for turning a pulley rim convex is to prevent the belt from

running off at one side, as it sometimes tends to do when a cylindrical

pulley is used.) The convex surface is produced by a special attachment

which causes the turning tool to gradually move outward as it feeds

down, until the center of the rim is reached, after which the movement

is inward.

The particular attachment shown in Fig. 12 consists of a special box-shaped tool-head F containing a sliding holder G,

in which the tool is clamped by set-screws passing through elongated

slots in the front of the tool-head. In addition, there is a radius link

L which swivels on a stud at the rear of the tool-head and is attached to vertical link H. Link L is so connected to the sliding tool-block that any downward movement of the tool-bar I

causes the tool to move outward until the link is in a horizontal

position, after which the movement is reversed. When the attachment is

first set up, the turning tool is placed at the center of the rim and

then link L is clamped to the vertical link while in a horizontal

position. The cut is started at the top edge of the rim, and the tool

is fed downward by power, the same as when turning a cylindrical

surface. The amount of curvature or convexity of a rim can be varied by

inserting the clamp bolt J in different holes in link L.

The tools for machining the hub and sides of the rim are held in a

turret mounted on the left-hand head, as shown. The special tool-holder A

contains two bent tools for turning the upper and lower edges of the

pulley rim at the same time as the tool-head is fed horizontally.

Roughing and finishing tools B are for facing the hub, and the tools C, D, and E rough bore, finish bore, and ream the hole for the shaft.

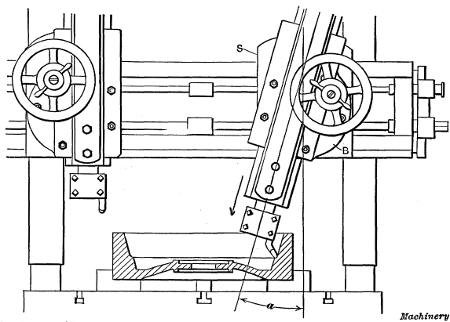

Fig. 13. Turning a Taper or Conical Surface

Turning Taper or Conical Surfaces.—Conical or taper surfaces are turned in a vertical boring mill by swiveling the tool-bar to the proper angle as shown in Fig. 13. When the taper is given in degrees, the tool-bar can be set by graduations on the edge of the circular base B, which show the angle a to which the bar is swiveled from a vertical position. The base turns on a central stud and is secured to the saddle S

by the bolts shown, which should be tightened after the tool-bar is

set. The vertical power feed can be used for taper turning the same as

for cylindrical work.

Fig. 14. Turning a Conical Surface by using the

Combined Vertical and Horizontal Feeds

Occasionally it is necessary to machine a conical surface which has

such a large included angle that the tool-bar cannot be swiveled far

enough around to permit turning by the method illustrated in Fig. 13.

Another method, which is sometimes resorted to for work of this class,

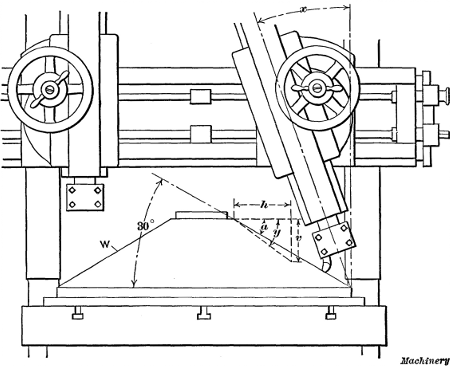

is to use the combined vertical and horizontal feeds. Suppose we want to

turn the conical casting W (Fig. 14), to an angle of 30 degrees, as shown, and that the tool-head of the boring mill moves horizontally 1/4 inch per turn of the feed-screw and has a vertical movement of 3/16 inch per turn of the upper feed-shaft. If the two feeds are used simultaneously, the tool will move a distance h of say 8 inches, while it moves downward a distance v of 6 inches, thus turning the surface to an angle y.

This angle is greater (as measured from a horizontal plane) than the

angle required, but, if the tool-bar is swiveled to an angle x,

the tool, as it moves downward, will also be advanced horizontally, in

addition to the regular horizontal movement. The result is that the

angle y is diminished and if the tool-bar is set over the right amount, the conical surface can be turned to an angle a of 30 degrees. The problem, then, is to determine what the angle x should be for turning to a given angle a.

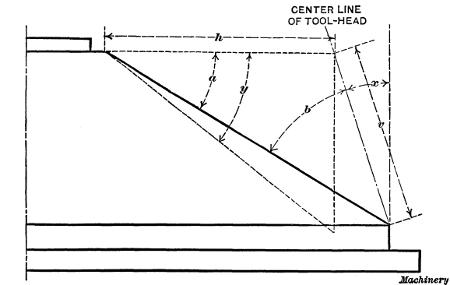

Fig. 15. Diagram showing Method of Obtaining Angular Position

of Tool-head when Turning Conical Surfaces by using Vertical and

Horizontal Feeding Movements

The way angle x is calculated will be explained in connection with the enlarged diagram, Fig. 15, which shows one-half of the casting. The sine of the known angle a is first found in a table of natural sines. Then the sine of angle b, between the taper surface and center-line of the tool-head, is determined as follows: sin b = (sin a × h) ÷ v, in which h represents the rate of horizontal feed and v the rate of vertical feed. The angle corresponding to sine b is next found in a table of sines. We now have angles b and a, and by subtracting the sum of these angles from 90 degrees, the desired angle x is obtained. To illustrate:

The sine of 30 degrees is 0.5; then sin b = (0.5 × 1/4) ÷ 3/16 = 0.6666; hence angle b = 41 degrees 49 minutes, and x = 90° - (30° + 41° 49') = 18 degrees 11 minutes. Hence to turn the casting to angle a

in a boring mill having the horizontal and vertical feeds given, the

tool-head would be set over from the vertical 18 degrees and 11 minutes

which is equivalent to about 181/6 degrees.

If the required angle a were greater than angle y

obtained from the combined feeds with the tool-bar in a vertical

position, it would then be necessary to swing the lower end of the bar

to the left rather than to the right of a vertical plane. When the

required angle a exceeds angle y, the sum of angles a and b is greater than 90 degrees so that angle x for the tool-head = (a + b) - 90 degrees.

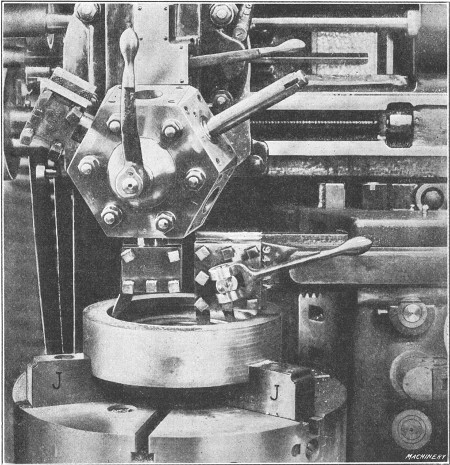

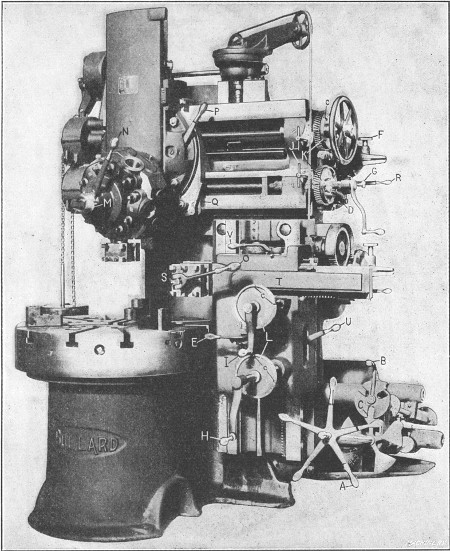

Fig. 16. Bullard Vertical Turret Lathe

Turret-lathe Type of Vertical Boring Mill.—The machine illustrated in Fig. 16

was designed to combine the advantages of the horizontal turret lathe

and the vertical boring mill. It is known as a “vertical turret lathe,”

but resembles, in many respects, a vertical boring mill. This machine

has a turret on the cross-rail the same as many vertical boring mills,

and, in addition, a side-head S. The side-head has a vertical feeding movement, and the tool-bar T

can be fed horizontally. The tool-bar is also equipped with a

four-sided turret for holding turning tools. This arrangement of the

tool-heads makes it possible to use two tools simultaneously upon

comparatively small work. When both heads are mounted on the cross-rail,

as with a double-head boring mill, it is often impossible to machine

certain parts to advantage, because one head interferes with the other.

The drive to the table (for the particular machine illustrated) is

from a belt pulley at the rear, and fifteen speed changes are available.

Five changes are obtained by turning the pilot-wheel A and this series of five speeds is compounded three times by turning lever B. Each spoke of pilot-wheel A indicates a speed which is engaged only when the spoke is in a vertical position, and the three positions for B are indicated, by slots in the disk shown. The number of table revolutions per minute for different positions of pilot-wheel A and lever B are shown by figures seen through whichever slot is at C.

There are five rows of figures corresponding to the five spokes of the

pilot-wheel and three figures in a row, and the speed is shown by arrows

on the sides of the slots. The segment disk containing these figures

also serves as an interlocking device which prevents moving more than

one speed controlling lever at a time, in order to avoid damaging the

driving mechanism.

The feeding movement for each head is independent. Lever D

controls the engagement or disengagement of the vertical or cross feeds

for the head on the cross-rail. The feed for the side-head is controlled

by lever E. When this lever is pushed inward, the entire head

feeds vertically, but when it is pulled out, the tool-bar feeds

horizontally. These two feeds can be disengaged by placing the lever in a

neutral position. The direction of the feeding movement for either head

can be reversed by lever R. The amount of feed is varied by feed-wheel F and clutch-rod G. When lever E is in the neutral position, the side-head or tool-bar can be adjusted by the hand-cranks H and I,

respectively. The cross-rail head and its turret slide have rapid power

traverse movements for making quick adjustments. This rapid traverse is

controlled by the key-handles J.

The feed-screws for the vertical head have micrometer dials K for making accurate adjustments. There are also large dials at L

which indicate vertical movements of the side head and horizontal

movements of the tool slide. All of these dials have small adjustable

clips c which are numbered to correspond to numbers on the faces

of the respective turrets. These clips or “observation stops” are used

in the production of duplicate parts. For example, suppose a tool in

face No. 1 for the main turret is set for a given diameter and height of

shoulder on a part which is to be duplicated. To obtain the same

setting of the tools for the next piece, clips No. 1, on both the

vertical feed rod and screw dials, are placed opposite the graduations

which are intersected by stationary pointers secured to the cross-rail.

The clips are set in this way after the first part has been machined to

the required size and before disturbing the final position of the tools.

For turning a duplicate part, the tools are simply brought to the same

position by turning the feed screws until the clips and stationary

pointers again coincide. For setting tools on other faces of either

turret, this operation is repeated, except that clips are used bearing

numbers corresponding to the turret face in use.

The main turret of this machine has five holes in which are

inserted the necessary boring and turning tools, drills or reamers, as

may be required. By having all the tools mounted in the turret, they can

be quickly and accurately set in the working position. When the turret

is indexed from one face to the next, binder lever N is first

loosened. The turret then moves forward, away from its seat, thus

disengaging the indexing and registering pins which accurately locate it

in any one of the five positions. The turret is revolved by turning

crank M, one turn of this handle moving the turret 1/5 revolution or from one hole to the next. The side-head turret is turned by loosening lever O. The turret slide can be locked rigidly in any position by lever P and its saddle is clamped to the cross-rail by lever Q. The binder levers for the saddle and toolslide of the side-head are located at U and V,

respectively. A slide that does not require feeding movements is locked

in order to obtain greater rigidity. To illustrate, if the main tool

slide were to feed vertically and not horizontally, it might be

advisable to lock the saddle to the cross-rail, while taking the

vertical cut.

The vertical slide can be set at an angle for taper turning, and

the turret is accurately located over the center of the table for boring

or reaming, by a positive center stop. The machine is provided with a

brake for stopping the work table quickly, which is operated by lifting

the shaft of pilot-wheel A. The side-and cross-rails are a unit

and are adjusted together to accommodate work of different heights. This

adjustment is effected by power on the particular machine illustrated,

and it is controlled by a lever near the left end of the cross-rail.

Before making this adjustment, all binder bolts which normally hold the

rails rigidly to the machine column must be released, and care should be

taken to tighten them after the adjustment is made.

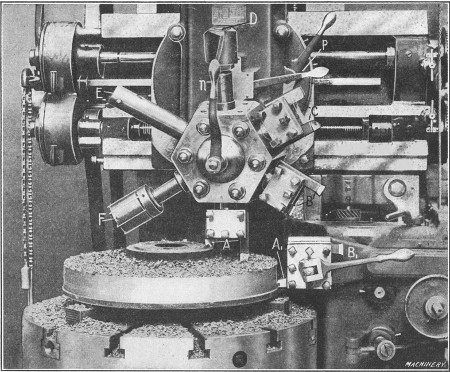

Fig. 17. Turning a Gear Blank on a Vertical Turret Lathe

Examples of Vertical Turret Lathe Work.—In order to

illustrate how a vertical turret lathe is used, one or two examples of

work will be referred to in detail. These examples also indicate, in a

general way, the class of work for which this type of machine is

adapted. Fig. 17 shows how a cast-iron gear

blank is machined. The work is gripped on the inside of the rim by three

chuck jaws, and all of the tools required for the various operations

are mounted in the main and side turrets. The illustration shows the

first operation which is that of rough turning the hub, the top side of

the blank and its periphery. The tools A for facing the hub and upper surface are both held in one tool-block on the main turret, and tool A1 for roughing the periphery is in the side turret. With this arrangement, the three surfaces can be turned simultaneously.

The main turret is next indexed one-sixth of a revolution which brings the broad finishing tools B into position, and the side turret is also turned to locate finishing tool B1

at the front. (The indexing of the main turret on this particular

machine is effected by loosening binder lever n and raising the turret

lock-pin by means of lever p.) The hub, side and periphery of the blank are then finished. When tools B

are clamped in the tool-blocks, they are, of course, set for turning

the hub to the required height. The third operation is performed by the

tools at C, one of which “breaks” or chamfers the corner of the cored hole in the hub, to provide a starting surface for drill D, and the other turns the outside of the hub, after the chamfering tool is removed. The four-lipped shell-drill D

is next used to drill the cored hole and then this hole is bored close

to the finished size and concentric with the circumference of the blank

by boring tool E, which is followed by the finishing reamer F.

When the drill, boring tool and reamer are being used, the turret is

set over the center or axis of the table, by means of a positive center

stop on the left-side of the turret saddle. If it is necessary to move

the turret beyond the central position, this stop can be swung out of

the way.

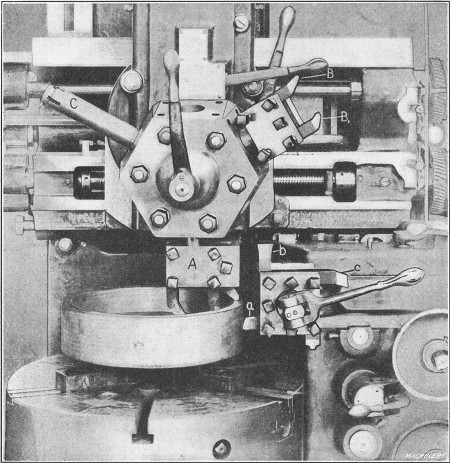

Fig. 18. Turning Gasoline Engine Flywheel on Vertical Turret Lathe—First Position

Fig. 19. Turning Gasoline Engine Flywheel—Second Position

Figs. 18 and 19

illustrate the turning of an automobile flywheel, which is another

typical example of work for a machine of this type. The flywheel is

finished in two settings. Its position for the first series of

operations is shown in Fig. 18, and the successive order of the four operations for the first setting is shown by the diagrams, Fig. 20. The first operation requires four tools which act simultaneously. The three held in tool-block A of the turret, face the hub, the web and the rim of the flywheel, while tool a in the side-head rough turns the outside diameter. The outside diameter is also finished by broad-nosed tool b which is given a coarse feed. In the second operation, the under face of the rim is finished by tool c, the outer corners are rounded by tool d and the inner surface of the rim is rough turned by a bent tool B,

which is moved into position by indexing the main turret. In the third

operation, the side-head is moved out of the way and the inside of the

rim is finished by another bent tool B1. The final operation at this setting is the boring of the central hole, which is done with a bar C having interchangeable cutters which make it possible to finish the hole at one setting of the turret.

Fig. 20. Diagrams showing How Successive Operations

are Performed by Different Tools in the Turret

The remaining operations are performed on the opposite side of the work which is held in “soft” jaws J accurately bored to fit the finished outside diameter as indicated in Fig. 19.

The tool in the main turret turns the inside of the rim, and the

side-head is equipped with two tools for facing the web and hub

simultaneously. As the tool in the main turret operates on the left side

of the rim, it is set with the cutting edge toward the rear. In order

to move the turret to this position, which is beyond the center of the

table, the center stop previously referred to is swung out of the way.

Floating Reamer Holders.—If a reamer is held rigidly in the

turret of a boring mill or turret lathe, it is liable to produce a hole

which tapers slightly or is too large. When a hole is bored with a

single-point boring tool, it is concentric with the axis of rotation,

and if a reamer that is aligned exactly with the bored hole is fed into

the work, the finished hole should be cylindrical and the correct size.

It is very difficult, however, to locate a reamer exactly in line with a

bored hole, because of slight variations in the indexing of the turret,

or errors resulting from wear of the guiding ways or other important

parts of the machine.

To prevent inaccuracies due to this cause, reamers are often held

in what is known as a “floating” holder. This type of holder is so

arranged that the reamer, instead of being held rigidly, is allowed a

slight free or floating movement so that it can follow a hole which has

been bored true, without restraint. In this way the hole is reamed

straight and to practically the same size as the reamer.

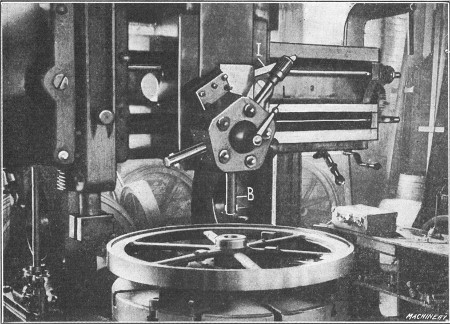

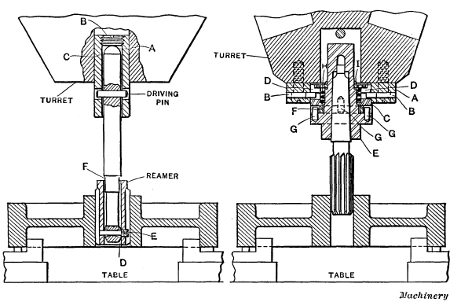

Fig. 21. Two Types of Floating Reamer Holders

There are many different designs of floating holders but the

general principle upon which they are based is illustrated by the two

types shown in Fig. 21. The reamer and holder shown to the left has a ball-shank A which bears against a backing-up screw B inserted in the end of holder C through which the driving pin passes. The lower end of the reamer shank is also spherical-shaped at D, and screw-pin E secures the shell reamer to this end. It will be noted that the hole in the shank for pin E is “bell-mouthed” on each side of the center and that there is clearance at F

between the shank and reamer shell; hence the reamer has a free

floating action in any direction. This holder has given very

satisfactory results.

The holder shown to the right is attached to the face of the turret by four fillister-head screws. Sleeve C is held in plate A by means of two steel pins B which are tight in plate A and made to fit freely in bayonet grooves D. Reamer holder E floats on sleeve C, the floating motion being obtained through the four steel pins G extending into driving ring F. Two of the pins are tight in the holder E and two in sleeve C. The faces of sleeve C, driving ring F, and reamer holder E are held tightly against each other by means of spring H which insures the reamer being held perfectly true. Spring H is adjusted by means of nut I

which is turned with a spanner wrench furnished with each holder. The

reamer is so held that its axis is always maintained parallel to the

center of the hole, and, at the same time, it has a slight

self-adjusting tendency radially, so that the hole and reamer will

automatically keep in perfect alignment with each other.

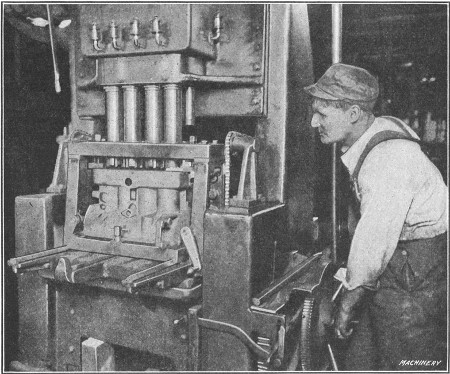

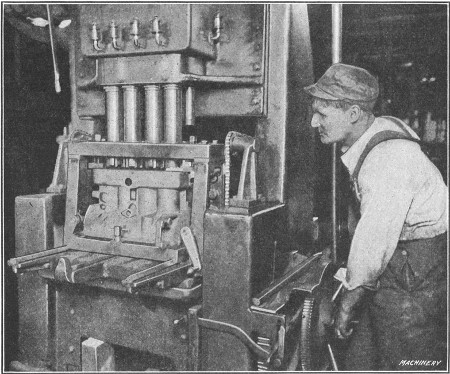

Fig. 22. Multiple-spindle Cylinder Boring Machine

Multiple Cylinder Boring Machine.—In automobile and other

factories where a great many gasoline engine cylinders are required,

multiple-spindle boring machines of the vertical type are commonly used.

The machine shown in Fig. 22 is a special design for boring four cylinders which are cast en bloc

or in one solid casting. The work is held in a box jig which has a top

plate equipped with guide bearings for holding the spindles rigidly

while boring. The lower end of each spindle has attached to it a

cutter-head and the boring is done by feeding the table and casting

vertically. This feeding movement is effected by power and it is

disengaged automatically when the cutters have bored to the required

depth. The particular machine illustrated is used for rough boring only,

the cylinders being finished by reaming in another similar machine. The

cylinders are bored to a diameter of 35/8 inches, and about 3/8

inch of metal is removed by the roughing cut. The spindles have fixed

center-to-center distances as the machine is intended for constant use

on cylinders of one size, so that adjustment is not necessary. Of

course, a special machine of this kind is only used in shops where large

numbers of cylinders of one design are required continually. Some

cylinder boring machines of the vertical type have spindles which can be

adjusted for different center-to-center distances if this should be

necessary in order to accommodate a cylinder of another size.

Return to Contents