|

Turning and

Boring on a Lathe

Online Reprint Chapter 4

This a complete book, published

in 1914, divided into chapters on how to use a metal lathe,

covering all turning and boring operations.

|

Return to Contents

Turning and Boring

by Franklin D. Jones

Published by Industrial Press 1914

A special treatise for machinists students in industrial and

engineering schools, and apprentices on turning and boring methods

including modern practice with engine lathes, vertical, and horizontal

boring machines.

Shop Amazon.com

|

CHAPTER IV

THREAD CUTTING IN THE LATHE

When threads are cut in the lathe a tool t is used (see Fig. 2),

having a point corresponding to the shape of the thread, and

the carriage is moved along the bed a certain distance for each

revolution of the work (the distance depending on the number

of threads to the inch being cut) by the lead-screw S which is

rotated by gears a, b and c, which receive their motion from the

spindle. As the amount that the carriage travels per revolution

of the work, and, consequently, the number of threads

per inch that is cut, depends on the size of the gears a and c

(called change gears) the latter have to be changed for cutting

different threads. The proper change gears to use for cutting

a given number of threads to the inch is ordinarily determined

by referring to a table or “index plate” I which shows what the

size of gears a and c should be, or the number of teeth each

should have, for cutting any given number of threads per inch.

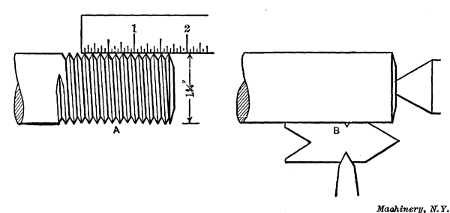

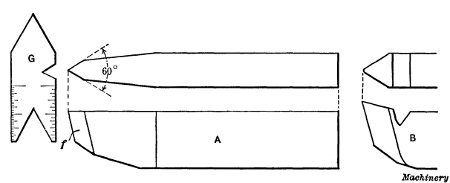

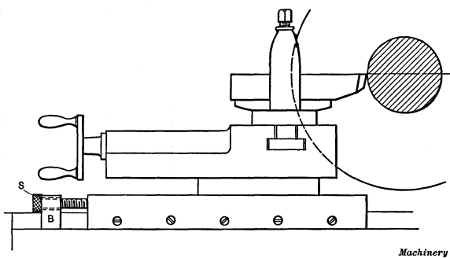

Fig. 1. Measuring Number of Threads per Inch—Setting Thread Tool

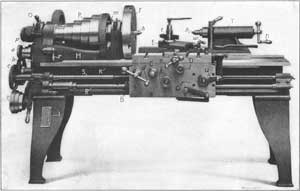

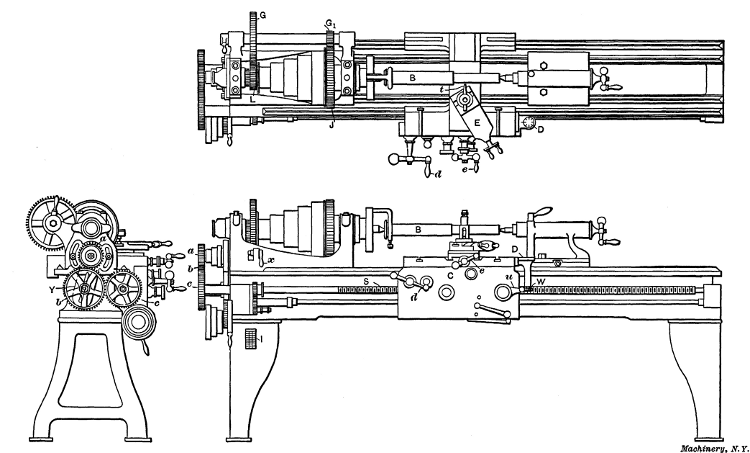

Fig. 2. Plan and Elevations of Engine Lathe

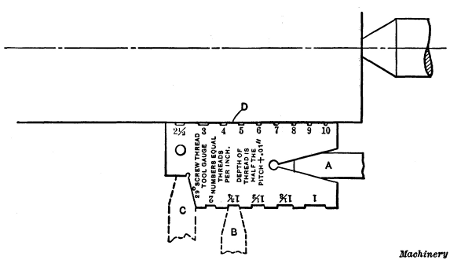

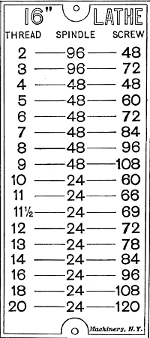

Selecting the Change Gears for Thread Cutting.—Suppose a

V-thread is to be cut on the end of the bolt B, Fig. 2, having

a diameter of 11/4 inch and seven threads per inch of length, as shown at A in Fig. 1, which is the standard number of threads

per inch for that diameter. First the change gears to use are

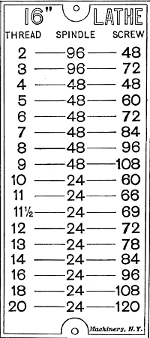

found on plate I which is shown enlarged in Fig. 3. This plate

has three columns: The first contains different numbers of

threads to the inch, the second the size gear to place on the

“spindle” or “stud” at a (Fig. 2) for different threads, and the

third the size of gear c for the lead-screw.

As the thread selected as

an example has 7 threads per inch,

gear a should have 48 teeth, this

being the number given in the

second column opposite figure 7

in the first. By referring to the

last column, we find that the

lead-screw gear should have 84

teeth. These gears are selected

from an assortment provided with

the lathe and they are placed on

the spindle and lead-screw, respectively.

Intermediate gear b does not

need to be changed as it is simply

an “idler” for connecting gears a

and c. Gear b is mounted on a

swinging yoke Y so that it can

be adjusted to mesh properly with

different gear combinations; after

this adjustment is made, the lathe

is geared for cutting 7 threads to

the inch. (The change gears of

many modern lathes are so arranged that different combinations

are obtained by simply shifting a lever. A lathe having this

quick-change gear mechanism is described in the latter part of

this chapter.) The work B is placed between the centers just

as it would be for turning, with the end to be threaded turned

to a diameter of 11/4 inch, which is the outside diameter of the

thread.

Fig. 3. Index Plate showing Gear Changes for Threading

The Thread Tool.—The form of tool used for cutting a

V-thread is shown at A, Fig. 4. The end is ground V-shaped

and to an angle of 60 degrees, which corresponds to the angle of

a standard V-thread. The front or flank, f of the tool is ground

back at an angle to provide clearance, but the top is left flat or

without slope. As it is very important to grind the end to exactly

60 degrees, a gage G is used, having 60-degree notches to

which the tool-point is fitted. The tool is clamped in the toolpost

as shown in the plan view, Fig. 2, square with the work, so

that both sides of the thread will be cut to the same angle with

the axis of the work. A very convenient way to set a thread

tool square is illustrated at B, Fig. 1. The thread gage is placed

against the part to be threaded, as shown, and the tool is adjusted

until the angular sides of the point bear evenly in the

60-degree notch of the gage. The top of the tool point should

be at the same height as the lathe centers, as otherwise the

angle of the thread will not be correct.

Fig. 4. Thread Tools and Gage for testing Angle of End

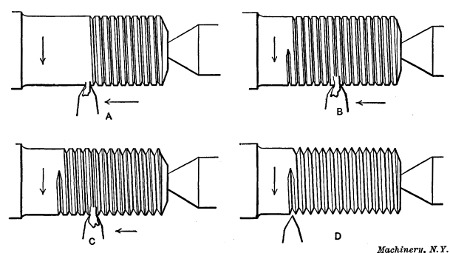

Cutting the Thread.—The lathe is now ready for cutting the

thread. This is done by taking several cuts, as indicated at A,

B, C and D in Fig. 5, the tool being fed in a little farther for

each successive cut until the thread is finished. When these

cuts are being taken, the carriage is moved along the bed, as

previously explained, by the lead-screw S, Fig. 2. The carriage

is engaged with the lead-screw by turning lever u which causes

the halves of a split nut to close around the screw. The way a lathe is

handled when cutting a thread is as follows: After the lathe is started,

the carriage is moved until the tool-point is slightly beyond the right

end of the work, and the tool is fed in far enough to take the first

cut which, ordinarily, would be about 1/16 inch deep. The carriage is then engaged with the

lead-screw, by operating lever u, and the tool moves to the left

(in this case 1/7 inch for each revolution of the work) and cuts a

winding groove as at A, Fig. 5. When the tool has traveled as

far as the thread is wanted, it is withdrawn by a quick turn of

cross-slide handle e, and the carriage is returned to the starting

point for another cut. The tool is then fed in a little farther

and a second cut is taken as at B, Fig. 5, and this operation is

repeated as at C and D until a “full” thread is cut or until the

top of the thread is sharp. The thread is then tested for size

but before referring to this part of the work, the way the carriage

is returned to the starting point after each cut should be

explained.

Fig. 5. Thread is formed by taking a Number of Successive Cuts

When the tool is withdrawn at the end of the first cut, if the

carriage is disengaged from the lead-screw and returned by

hand, the tool may or may not follow the first cut when the carriage

is again engaged with the lead-screw. If the number of

threads to the inch being cut is a multiple of the number on the

lead-screw S, then the carriage can be returned by hand and

engaged with the lead-screw at random and the tool will follow the first

cut. For example, if the lead-screw has six threads per inch, and 6,

12, 18 or any number of threads is being cut that is a multiple of six,

the carriage can be engaged at any time and the tool will always follow

the original cut. This is not the case, however, when the number of

threads being cut is not a multiple of the number on the lead-screw.

One method of bringing the carriage back to the starting point,

when cutting threads which are not multiples, is to reverse the

lathe (by shifting the overhead driving belts) in order to bring

the tool back to the starting point without disengaging the

carriage; in this way the tool is kept in the same relation to the

work, and the carriage is not disengaged from the lead-screw

until the thread is finished. This is a good method when cutting

short threads having a length of say two or three inches;

but when they are longer, and especially when the diameter is

comparatively large (which means a slower speed), it is rather

slow as considerable time is wasted while the tool is moving

back to its starting point. This is due to the fact that the

carriage is moved slowly by the lead-screw, but when disengaged,

it can be traversed quickly by turning handle d, Fig. 2.

A method of returning the carriage by hand when the number of threads

being cut is not a multiple of the number on the lead-screw is as

follows: The tool is moved a little beyond the right end of the work and

the carriage or split nut is engaged with the lead-screw. The lathe is

then turned forward by hand to take up any lost motion, and a line is

made on the lathe bed showing the position of the carriage. The

positions of the spindle and lead-screw are also marked by chalking a

tooth on both the spindle and lead-screw gears, which happens to be

opposite a corner or other point on the bed. After a cut is taken, the

carriage is returned by hand to the original starting point as shown by

the line on the bed, and is again engaged when the chalk marks show that

the spindle and lead-screw are in their original position; the tool

will then follow the first cut. If the body of the tailstock is moved

against the bridge of the carriage before starting the first cut, the

carriage can be located for each following cut by moving it back against

the tailstock, and it will not be necessary to have a line on the bed.

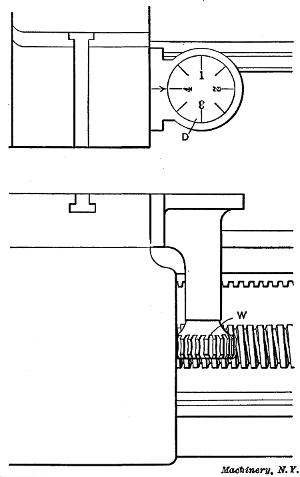

Fig. 6. Indicator used when Cutting Threads

Indicator or Chasing Dial for Catching Threads.—On some

lathes there is an indicator for “catching threads,” as this is

called in shop language. This is a simple device attached to

the carriage and consists

of a graduated

dial D and a worm-wheel

W (see Figs. 2

and 6) which meshes

with the lead-screw,

so that the dial is

revolved by the lead-screw

when the carriage

is stationary,

and when the carriage

is moved by the screw,

the dial remains stationary.

The indicator

is used by engaging

the carriage when

one of the graduation

lines is opposite the

arrow mark; after a

cut is taken the carriage

is returned by

hand and when one of

the graduation lines

again moves opposite

the arrow, the half-nuts are thrown into mesh, as before, and

this is repeated for each successive cut, thus causing the tool to

always come right with the thread. If the number of threads per

inch is even, engagement can be made when any line is opposite

the arrow, but for odd numbers such as 3, 7, 9, 11, etc., one of

the four long or numbered lines must be used. Of course, if the

thread being cut is a multiple of the number on the lead-screw,

engagement can be made at any time, as previously mentioned.

Principle of the Thread Indicator.—The principle upon

which the thread indicator operates is as follows: The number

of teeth in worm-wheel W is some multiple of the number of

threads per inch of the lead-screw, and the number of teeth in

the worm-wheel, divided by the pitch of the screw, equals the

number of graduations on the dial. For example, if the lead-screw

has six threads per inch, the worm-wheel could have

twenty-four teeth, in which case the dial would have four divisions,

each representing an inch of carriage travel, and by sub-dividing

the dial into eighths (as shown) each line would correspond

to 1/2 inch of travel. The dial, therefore, would enable

the carriage to be engaged with the lead-screw at points equal

to a travel of one-half inch. To illustrate the advantage of this

suppose ten threads per inch are being cut and (with the lathe

stationary) the carriage is disengaged and moved 1/6 inch or one

thread on the lead-screw; the tool point will also have moved

1/6 inch, but it will not be opposite the next thread groove in the

work as the pitch is 1/10 inch. If the carriage is moved another

thread on the lead-screw, or 2/6 inch, the tool will still be out of

line with the thread on the work, but when it has moved three

threads, or 1/2 inch, the tool will then coincide with the original

cut because it has passed over exactly five threads. This would

be true for any number of threads per inch that is divisible by

2. If the thread being cut had nine threads per inch or any

other odd number, the tool would only coincide with the thread

at points 1 inch apart. Therefore, the carriage can only be

engaged when one of the four graduations representing an inch

of travel is opposite the arrow, when cutting odd threads;

whereas even numbers can be “caught” by using any one of the

eight lines.

This indicator can also be used for “catching” fractional

threads. As an illustration, suppose 111/2

threads per inch are to be cut, and the carriage is engaged for the

first cut when graduation line 1 is opposite the arrow; engagement would

then be made for each successive cut, when either line 1 or 3 were

opposite the arrow, or in other words at spaces equal to a carriage

movement of 2 inches. As the use of the indicator when cutting

fractional threads is liable to result in error, it is better to keep

the half-nuts in engagement and return the carriage by reversing the

lathe.

Replacing Sharpened Thread Tool.—If it is necessary to

sharpen the thread tool before the thread is finished, it should

be reset square with the work by testing with the thread gage

as at B, Fig. 1. The carriage is then engaged with the lead-screw

and the lathe is turned forward to bring the tool opposite

the partly finished thread and also to take up any backlash or

lost motion in the gears or half-nut. If the tool-point is not

in line with the thread groove previously cut, it can be shifted

sidewise by feeding the compound rest E in or out, provided

the latter is set in an angular position as shown in the plan

view, Fig. 2.

If the thread tool is ground flat on the top as at A, Fig. 4, it

is not a good tool for removing metal rapidly as neither of its

two cutting edges has any slope. In order to give each cutting

edge a backward slope, it would be necessary to grind the

top surface hollow or concave, which would be impracticable.

When a course thread is to be cut, a tool shaped as at B can be

used to advantage for rough turning the thread groove, which

is afterward finished to the correct depth and angle by tool A.

This roughing tool is ground with a backward slope from the

point and the latter is rounded to make it stronger.

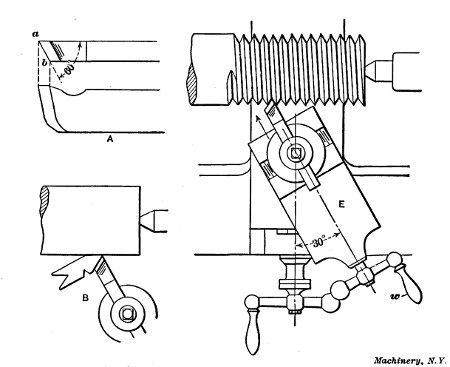

Fig. 7. Cutting Thread by using Compound Rest

Use of Compound Rest for Thread Cutting.—Another form

of thread tool is shown at A, Fig. 7, which is very good for

cutting V-threads especially of coarse pitch. When this tool is

used, the compound rest E is set to an angle of 30 degrees, as

shown, and it is fed in for the successive cuts by handle w in the

direction indicated by the arrow. It will be seen that the point

a of the tool moves at an angle of 60 degrees with the axis of

the work, thus forming one side of the thread, and the cutting

edge a—b, which can be set as shown at B, forms the

opposite side and does all the cutting. As this edge is given a backward

slope, as shown, it cuts easily and enables threading operations to be

performed quickly. Threads cut in this way are often finished by taking a

light cut with a regular thread tool. The cutting edge a—b is ground to an angle of 60 degrees (or slightly

less, if anything) with the side, as shown by sketch A.

When cutting threads in steel or wrought iron, some sort of

lubricant is usually applied to the tool to preserve the cutting

end and give a smooth finish to the thread. Lard oil or a mixture

of equal parts of lard oil and paraffin oil are often used for this

purpose. If the thread is small, the lubricant may be applied

from an ordinary oil can, but when cutting comparatively large

threads, it is better to have a stream of oil constantly playing

upon the tool-point. This constant flow may be obtained by

mounting a can having a spout leading to the tool, on a bracket

at the rear of the carriage.

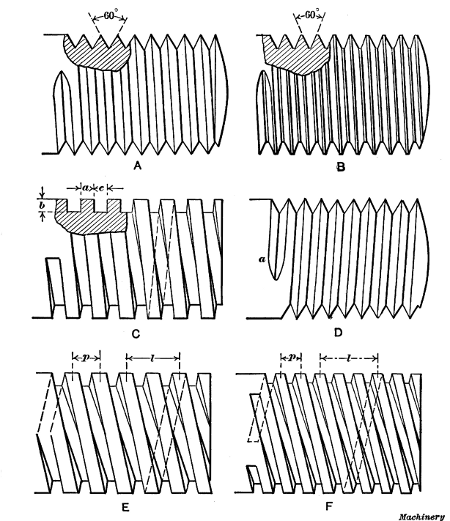

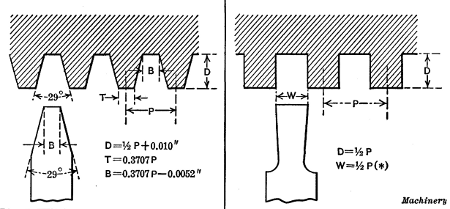

Fig. 8. (A) V-thread.

(B) U. S. Standard Thread.

(C) Square Thread.

(D)

Left-hand Thread.

(E) Double Square Thread.

(F) Triple Square Thread

Threads Commonly Used.—Three forms of threads or screws

which are in common use are shown in Fig. 8; these are the

V-thread (A), the U. S. standard (B), and the square thread

(C). The shapes of these threads are shown by the sectioned

parts. The V-thread has straight sides which incline at an angle of 60

degrees with each other and at the same angle with the axis of the

screw. The U. S. standard thread is similar to the V-thread except that

the top of the thread and bottom of the groove is left flat, as shown,

and the width of these flats is made equal to 1/8 of the pitch. The square thread is square in

section, the width a, depth b and space c being all

equal. All of these threads are right-hand, which means that the

grooves wind around to the right so that a nut will have to be turned

toward the right to enter it on the thread. A left-hand thread winds in

the other direction, as shown at D, and a nut is screwed

on by turning it to the left.

Multiple Threads.—Threads, in addition to being right-and

left-handed, are single, as at A, B, C and D, double, as at E,

and triple, as at F, and for certain purposes quadruple threads

or those of a higher multiple are employed. A double thread

is different from a single thread in that it has two grooves,

starting diametrically opposite, whereas a triple thread has three

grooves cut as shown at F. The object of these multiple

threads is to obtain an increase in lead without weakening the

screw. For example, the threads shown at C and E have the

same pitch p but the lead l of the double-threaded screw is

twice that of the one with a single thread so that a nut would

advance twice as far in one revolution, which is often a very

desirable feature. To obtain the same lead with a single thread,

the pitch would have to be double, thus giving a much coarser

thread, which would weaken the screw, unless its diameter

were increased. (The lead is the distance l that one thread advances

in a single turn, or the distance that a nut would advance

in one turn, and it should not be confused with the pitch p,

which is the distance between the centers of adjacent threads.

Obviously the lead and pitch of a single thread are the same.)

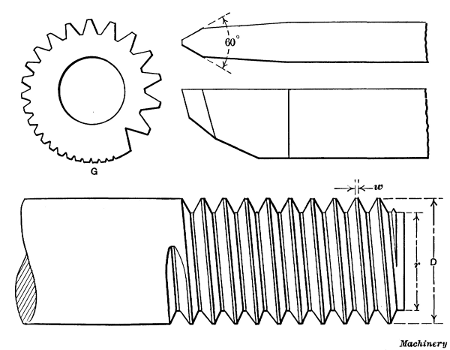

Fig. 9. U. S. Standard Thread, Thread Tool, and Gage

Cutting a U. S. Standard Thread.—The method of cutting a

U. S. standard thread is the same as described for a V-thread,

so far as handling the lathe is concerned. The thread tool

must correspond, of course, to the shape of a U. S. standard

thread. This tool is first ground to an angle of 60 degrees, as

it would be for cutting a V-thread, and then the point is made

flat as shown in Fig. 9. As will be recalled, the width of this

flat should be equal to 1/8 of the pitch. By using a gage like the

one shown at G, the tool can easily be ground for any pitch, as

the notches around the periphery of the gage are marked for

different pitches and the tool-point is fitted into the notch corresponding

to the pitch wanted. If such a gage is not available, the

width of the flat at the point can be tested by using, as a gage,

a U. S. standard tap of the same pitch as the thread to be cut.

When cutting the thread, the tool is set square with the blank, and a

number of successive cuts are taken, the tool being fed in until the

width w of the flat at the top of the thread is equal to the width at

the bottom. The thread will then be the right size provided the outside

diameter D is correct and the tool is

of the correct form. As it would be difficult to measure the

width of this flat accurately, the thread can be tested by screwing

a standard nut over it if a standard thread is being cut. If

it is being fitted to a tapped hole, the tap itself is a very convenient

gage to use, the method being to caliper the tap and

then compare its size with the work.

A good method of cutting a U. S. standard thread to a given

size is as follows: First turn the outside of the blank accurately

to diameter D, and then turn a small part of the end to diameter

r of the thread at the root. The finishing cut for the thread

is then taken with the tool point set to just graze diameter r.

If ordinary calipers were set to diameter r and measurements

taken in the thread groove, the size would be incorrect owing to the

angularity of the groove, which makes it necessary to hold the calipers

at an angle when measuring. To determine the root diameter divide 1.299

by the number of threads per inch and subtract the quotient from the

outside diameter. Expressing this rule as a formula,

in which D equals outside diameter; N, the number of threads

per inch; and r, the root diameter. The number 1.299 is a constant

that is always used.

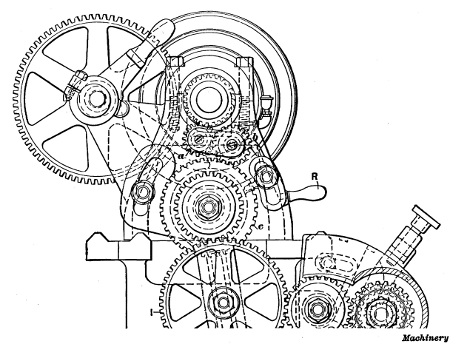

Fig. 10. End View of Lathe Headstock

Cutting a Left-hand Thread.—The only difference between

cutting left-hand and right-hand threads in the lathe is in the

movement of the tool with relation to the work. When cutting

a right-hand thread, the tool moves from right to left, but this

movement is reversed for left-hand threads because the thread

winds around in the opposite direction. To make the carriage

travel from left to right, the lead-screw is rotated backwards

by means of reversing gears a and b (Fig. 10) located in the headstock. Either of these gears can be engaged with the spindle gear by changing the position of lever R. When gear a

is in engagement, as shown, the drive from the spindle to gear

c is through gears a and b, but when lever R is raised thus shifting

b into mesh, the drive is direct and the direction of rotation

is reversed. The thread is cut by starting the tool at a, Fig. 8,

instead of at the end.

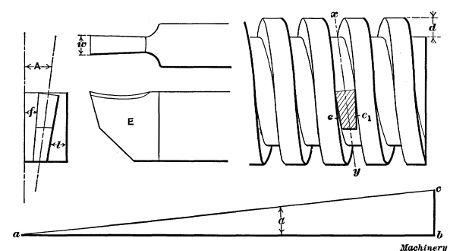

Fig. 11. End of Square Thread Tool, and Graphic Method of

Determining Helix Angle of Thread

Cutting a Square Thread.—The form of tool used for cutting

a square thread is shown in Fig. 11. The width w is made

equal to one-half the pitch of the thread to be cut and the end E

is at an angle with the shank, which corresponds to the inclination

x—y of the threads. This angle A depends upon the

diameter of the screw and the lead of the thread; it can be determined

graphically by drawing a line a—b equal in length to

the circumference of the screw to be cut, and a line b—c, at right

angles, equal in length to the lead of the thread. The angle α

between lines a—b and a—c will be the required angle A. (See

end view of thread tool). It is not necessary to have this angle

accurate, ordinarily, as it is simply to prevent the tool from

binding against the sides of the thread. The end of a square

thread tool is shown in section to the right, to illustrate its

position with relation to the threads. The sides e and e1 are

ground to slope inward, as shown, to provide additional clearance.

When cutting multiple threads, which, owing to their increased lead,

incline considerably with the axis of the screw, the angles for each

side of the tool can be determined independently as follows: Draw line a—b equal in length to the circumference

of the thread, as before, to obtain the required

angle f of the rear or following side e1; the angle l of the opposite

or leading side is found by making a—b equal to the circumference

at the root of the thread. The tool illustrated is for

cutting right-hand threads; if it were intended for a left-hand

thread, the end, of course, would incline in the opposite direction.

The square thread is cut so that the depth d is equal to

the width. When threading a nut for a square thread screw, it

is the usual practice to use a tool having a width slightly greater

than one-half the pitch, to provide clearance for the screw, and

the width of a tool for threading square-thread taps to be used

for tapping nuts is made slightly less than one-half the pitch.

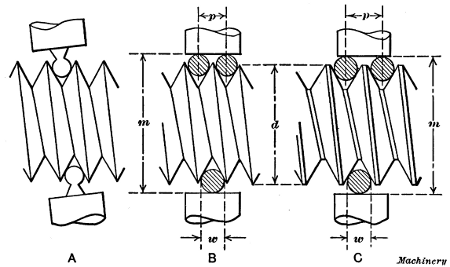

Fig. 12. Views illustrating how a Double Square Thread is Cut

Cutting Multiple Threads.—When a multiple thread is to be

cut, such as a double or triple thread, the lathe is geared with

reference to the number of single threads to the inch. For example,

the lead of the double thread, shown at B, Fig. 12, is

one-half inch, or twice the pitch, and the number of single

threads to the inch equals 1 ÷ 1/2 = 2. Therefore, the lathe is

geared for cutting two threads per inch. The first cut is taken

just as though a single thread were being cut, leaving the work

as shown at A. When this cut is finished the work is turned

one-half a revolution (for a double thread) without disturbing

the position of the lead-screw or carriage, which brings the tool

midway between the grooves of the single thread as indicated

by dotted lines. The second groove is then cut, producing a

double thread as shown at B. In the case of a triple thread,

the work would be indexed one-third of a revolution after turning

the first groove, and then another third revolution to locate

the tool for cutting the last groove. Similarly, for a quadruple

thread, it would be turned one-quarter revolution after cutting

each successive groove or thread.

There are different methods of indexing the work when cutting

multiple threads, in order to locate the tool in the proper position for

cutting another thread groove. Some machinists, when cutting a double

thread, simply remove the work from the lathe and turn it one-half a

revolution by placing the tail of the driving dog in the opposite slot

of the faceplate. This is a very simple method, but if the slots are not

directly opposite or 180 degrees apart, the last thread will not be

central with the first. Another and better method is to disengage the

idler gear from the gear on the stud, turn the spindle and work

one-half, or one-third, of a revolution, as the case might be, and then

connect the gears. For example, if the stud gear had 96 teeth, the tooth

meshing with the idler gear would be marked with chalk, the gears

disengaged, and the spindle turned until the chalked tooth had made the

required part of a revolution, which could be determined by counting the

teeth. When this method is used, the number of teeth in the stud gear

must be evenly divisible by two if a double thread is being cut, or by

three for a triple thread, etc. If the stud is not geared to the spindle

so that each makes the same number of revolutions, the ratio of the

gearing must be considered.

Setting Tool When Cutting Multiple Threads.—Another

method, which can sometimes be used for setting the tool after

cutting the first groove of a multiple thread, is to disengage the

lock-nuts from the lead-screw (while the spindle is stationary)

and move the carriage back whatever distance is required to

locate the tool in the proper position for taking the second cut.

Evidently this distance must not only locate the tool in the right

place, but be such that the lock-nuts can be re-engaged with

the lead-screw. Beginning with a simple illustration, suppose a

double thread is being cut having a lead of 1 inch. After the

first thread groove is cut, the tool can be set in a central position

for taking the second cut, by simply moving the carriage back

1/2 inch (one-half the lead), or 1/2 inch plus the lead or any

multiple of the lead. If the length of the threaded part were

5 inches, the tool would be moved back far enough to clear the

end of the work, or say 1/2 + 5 = 51/2 inches. In order to disengage

the lock-nuts and re-engage them after moving the carriage

51/2 inches (or any distance equal, in this case, to one-half

plus a whole number), the lead-screw must have an even number

of threads per inch.

Assume that a double thread is being cut having 11/4 single

threads per inch. The lead then would equal 1 ÷ 11/4 = 0.8

inch, and if the carriage is moved back 0.8 ÷ 2 = 0.4 inch, the

tool will be properly located for the second cut; but the lock-nuts

could not be re-engaged unless the lead-screw had ten

threads per inch, which is finer than the pitch found on the

lead-screws of ordinary engine lathes. However, if the movement

were 0.4 + 0.8 × 2 = 2 inches, the lock-nuts could be re-engaged

regardless of the number of threads per inch on the

lead-screw. The rule then, is as follows:

Divide the lead of the thread by 2 for a double thread, 3 for a

triple thread, 4 for a quadruple thread, etc., thus obtaining the

pitch; then add the pitch to any multiple of the lead, which will

give a movement, in inches, that will enable the lock-nuts to be re-engaged

with the lead-screw.

Whenever the number obtained by this rule is a whole number,

obviously, the movement can be obtained with a lead-screw of any pitch.

If the number is fractional, the number of threads per inch on the

lead-screw must be divisible by the denominator of the fraction.

To illustrate the application of the foregoing rule, suppose a

quadruple thread is to be cut having 11/2 single threads per inch

(which would be the number the lathe would be geared to cut).

Then the lead of the thread = 1 ÷ 11/2 = 0.6666 inch and the

pitch = 0.6666 ÷ 4 = 0.1666 inch; adding the pitch to twice

the lead we have 0.1666 + 2 × 0.6666 = 1.499 inch. Hence, if

the carriage is moved 11/2 inch (which will require a lead-screw

having an even number of threads per inch), the tool will be

located accurately enough for practical purposes. When the

tool is set in this way, if it does not clear the end of the part

being threaded, the lathe can be turned backward to place the

tool in the proper position.

The foregoing rule, as applied to triple threads or those of a

higher number, does not always give the only distance that the

carriage can be moved. To illustrate, in the preceding example

the carriage movement could be equal to 0.499, or what is practically

one-half inch, instead of 11/2 inch, and the tool would be

properly located. The rule, however, has the merit of simplicity

and can be used in most cases.

Fig. 13. Indexing Faceplate used for Multiple Thread Cutting

Special faceplates are sometimes used for multiple thread

cutting, that enable work to be easily and accurately indexed.

One of these is illustrated in Fig. 13; it consists of two parts Aand B, part A being free to rotate in relation to B when bolts C

are loosened. The driving pin for the lathe dog is attached to

plate A. When one groove of a multiple thread is finished,

bolts C are loosened and plate A is turned around an amount

corresponding to the type of thread being cut. The periphery

of plate A is graduated in degrees, as shown, and for a double

thread it would be turned one-half revolution or 180 degrees,

for a triple thread, 120 degrees, etc. This is a very good arrangement

where multiple thread cutting is done frequently.

Fig. 14. Correct and Incorrect Positions of Tool for Taper Thread Cutting

Taper Threading.—When a taper thread is to be cut, the

tool should be set square with axis a—a as at A, Fig. 14, and

not by the tapering surface as at B. If there is a cylindrical

part, the tool can be set as indicated by the dotted lines. All

taper threads should be cut by the use of taper attachments.

If the tailstock is set over to get the required taper, and an

ordinary bent-tail dog is used for driving, the curve of the

thread will not be true, or in other words the thread will not

advance at a uniform rate; this is referred to by machinists as

a “drunken thread.” This error in the thread is due to the

angularity between the driving dog and the faceplate, which

causes the work to be rotated at a varying velocity. The pitch

of a taper thread that is cut with the tailstock set over will also

be slightly finer than the pitch for which the lathe is geared.

The amount of these errors depends upon the angle of the taper

and the distance that the center must be offset.

Fig. 15. Method of setting and using Inside Thread Tool

Internal Threading.—Internal

threading, or cutting threads in holes, is an operation performed on

work held in the chuck or on a faceplate, as for boring. The tool used

is similar to a boring tool except that the working end is shaped to

conform to the thread to be cut. The method of procedure, when cutting

an internal thread, is similar to that for outside work, as far as

handling the lathe is concerned. The hole to be threaded is first bored

to the root diameter D, Fig. 15, of the screw that is

to fit into it. The tool-point (of a tool for a U. S. standard or

V-thread) is then set square by holding a gage G against the

true side of the work and adjusting the point to fit the notch in

the gage as shown. The view to the right shows the tool taking

the first cut.

Very often the size of a threaded hole can be tested by using

as a gage the threaded part that is to fit into it. When making

such a test, the tool is, of course, moved back out of the way.

It is rather difficult to cut an accurate thread in a small hole,

especially when the hole is quite deep, owing to the flexibility

of the tool; for this reason threads are sometimes cut slightly

under size with the tool, after which a tap with its shank end

held straight by the tailstock center is run through the hole.

In such a case, the tap should be calipered and the thread made

just small enough with the tool to give the tap a light cut.

Small square-threaded holes are often finished in this way, and

if a number of pieces are to be threaded, the use of a tap makes

the holes uniform in size.

Fig. 16. Cross-slide equipped with Stop for Regulating Depth

of Cut when Threading

Stop for Thread Tools.—When

cutting a thread, it is rather difficult to feed in the tool just the

right amount for each successive cut, because the tool is moved in

before it feeds up to the work. A stop is sometimes used for threading which overcomes this difficulty. This stop consists of a screw S, Fig. 16,

which enters the tool slide and passes through a block B clamped

in front of the slide. The hole in the block through which the

stop-screw passes is not threaded, but is large enough to permit

the screw to move freely. When cutting a thread, the tool is

set for the first cut and the screw is adjusted until the head is

against the fixed block. After taking the first cut, the stop-screw

is backed out, say one-half revolution, which allows the

tool to be fed in far enough for a second cut. If this cut is

about right for depth, the screw is again turned about one-half

revolution for the next cut and this is continued for each successive

cut until the thread is finished. By using a stop of this

kind, there is no danger of feeding the tool in too far as is often

done when the tool is set by guess. If this form of stop is used

for internal threading, the screw, instead of passing through the

fixed block, is placed in the slide so that the end or head will

come against the stop B. This change is made because the tool

is fed outward when cutting an internal thread.

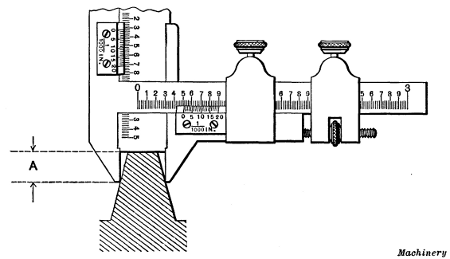

Fig. 17. Gage for grinding and setting Acme Thread Tools

The Acme Standard Thread.—The Acme thread is often

used, at the present time, in place of a square thread. The

angle between the sides of the Acme thread is 29 degrees (see

Fig. 21) and the depth is made equal to one-half

the pitch plus 0.010 inch to provide clearance and insure a bearing

upon the sides. The thread tool is ordinarily ground to fit a gage

having notches representing different pitches. An improved form of Acme

thread gage is shown in Fig. 17. The tool point is first

ground to the correct angle by fitting it to the 29-degree notch

in the end of the gage, as at A. The end is then ground to the

proper width for the pitch to be cut, by testing it, as at B. The

numbers opposite the shallow notches for gaging the width represent

the number of threads per inch. With this particular gage,

the tool can be set square by placing edge D against the turned

surface to be threaded, and adjusting the tool until the end is in

line with the gage, as at C. By placing the tool in this position,

the angle between the side and the end can also be tested.

Fig. 18. Measuring Width of Acme Thread Tool with Vernier Gear-tooth

Caliper

In case it should be necessary to measure the end width of

an Acme thread tool, for a pitch not on the regular gage, this

can be done by using a vernier gear-tooth caliper, as indicated

in Fig. 18. If we assume that the caliper jaws bear on the sides

of the tool at a distance A from the top, equal to 1/4

inch, then the width of the tool point equals the caliper reading (as

shown by the horizontal scale) minus 0.1293 inch. For example, if the

caliper reading was 0.315 inch, the width at the point would equal 0.315

- 0.1293 = 0.1857 inch, assuming that the sides were ground to the

standard angle of 29 degrees. The constant to be subtracted from the

caliper reading equals 2 A tan 14° 30'

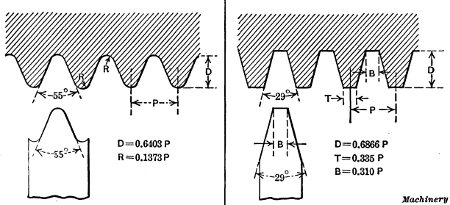

or, in this case, 2 × 0.25 × 0.2586 = 0.1293.

The Whitworth Thread.—The Whitworth (or British Standard

Whitworth) thread, which is used principally in Great

Britain, has an included angle of 55 degrees, and the threads

are rounded at the top and at the root, as shown in Fig. 23.

The shape of the tool used for cutting this thread is also shown

in this illustration. The end is rounded to form the fillet at

the root of the thread, and the round corners on the sides give

the top of the thread the required curvature. Every pitch requires

a different tool, and the cutting end is given the curved

form by milling or hobbing. The hob used for this purpose is

accurately threaded to correspond with the pitch for which

the tool is required, and then it is fluted to form cutting edges,

and is hardened. The hob is then used like a milling cutter

for forming the end of the thread tool. The tool is sharpened

by grinding on the top. The method of cutting a Whitworth

thread is, of course, similar to that followed for a U. S. standard

or V-thread, in that the tool is set square with the unthreaded

blank and at the same height as the lathe centers, in order to

secure a thread of the proper form. Care should be taken to

turn the blank to the right diameter so that the top of the

thread will be fully rounded when the screw is the required size.

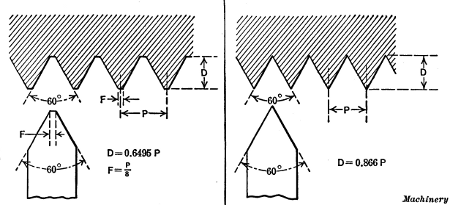

Fig. 19. United States Standard Thread

Fig. 20. Standard Sharp V-thread

Fig. 21. Acme Standard Thread

Fig. 22. Square Thread

Fig. 23. Whitworth Standard Thread

Fig. 24. Standard Worm Thread

Worm Threads.—The standard worm thread has an angle

of 29 degrees between the sides, the same as an Acme thread,

but the depth of a worm thread and the width of the flat at the

top and bottom differ from the Acme standard, as will be seen

by comparing Figs. 21 and 24. The whole depth of the thread

equals the linear pitch multiplied by 0.6866, and the width of

the thread tool at the end equals the linear pitch multiplied by

0.31. Gages notched for threads of different pitch are ordinarily

used when grinding worm thread tools.

When it is necessary to cut multiple-threaded worms of large

lead in an ordinary lathe, difficulty is sometimes experienced

because the lead-screw must be geared to run much faster than

the spindle, thus imposing excessive strains on the gearing.

This difficulty is sometimes overcome by mounting a belt pulley

on the lead-screw, beside the change gear, and connecting

it to the countershaft by a belt; the spindle is then driven

through the change gearing from the lead-screw, instead of vice

versa.

Coarse Threading Attachment.—To avoid the difficulties

connected with cutting threads of large lead, some lathes are

equipped with a coarse screw-cutting attachment. The arrangement

of this attachment, as made by the Bradford Machine

Tool Co., is as follows: On the usual reversing shaft, and inside

of the headstock, there is a sliding double gear, so arranged as

to be engaged with either the usual gear on the spindle, or with

a small pinion at the end of the cone. The gears are so proportioned

that the ratio of the two engagements is as 10 to 1;

that is, when engaged with the cone gear (the back-gears being

thrown in) the mating gear will make ten revolutions to one of

the spindle, so that when the lathe is ordinarily geared to cut

one thread per inch, it will, when driven by the cone pinion,

cut one thread in ten inches. This construction dispenses with

the extra strain on the reverse gears due to moving the carriage

at the rapid rate that would be necessary for such a large

lead, when not using an attachment. These attachments are

not only extensively used for the cutting of coarse screws but

for cutting oil grooves on cylindrical parts.

When cutting a thread

of large lead or “steep pitch,” the top

of the thread tool should be ground so that it is at right angles

to the thread; then the thread groove will be cut to the same

width as the tool.

Testing the Size of a Thread.—When the thread tool has

been fed in far enough to form a complete thread, the screw is

then tested for size. If we assume that a bolt is being threaded

for a standard nut, it would be removed from the lathe and the

test made by screwing a nut on the end. If the thread were

too large, the nut might screw on very tightly or not at all; in

either case, the work would again be placed in the lathe and a

light cut taken over it to reduce the thread to the proper size.

When replacing a threaded part between the centers, it should

be put back in the original position, that is, with the “tail” of

the driving dog in the same slot of the faceplate it previously

occupied.

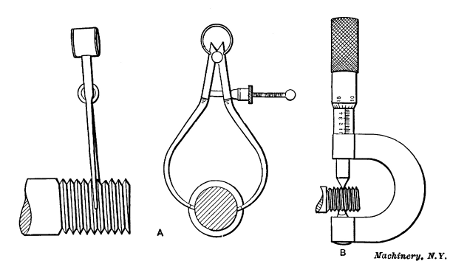

Fig. 25. Testing Diameter of Thread with Calipers and Micrometer

As it is difficult to tell just when a thread is cut to the exact

size, special thread calipers having wedge-shaped ends are

sometimes used for measuring the diameter of a V-thread or a

U. S. standard thread, at the bottom of the grooves or the root

diameter, as shown at A in Fig. 25. These calipers can be set

from a tap corresponding to the size of the thread being cut, or

from a previously threaded piece of the right size.

The Thread Micrometer.—Another form of caliper for testing

threads is shown at B. This is one of the micrometer type

and is intended for very accurate work. The spindle of this

micrometer has a conical end and the “anvil” is V-shaped,

and these ends bear on the sides of the thread or the surfaces

which form the bearing when the screw is inserted in a nut or

threaded hole. The cone-shaped point is slightly rounded so

that it will not bear in the bottom of the thread. There is also

sufficient clearance at the bottom of the V-shaped anvil to prevent

it from bearing on top of the thread. The diameter as

indicated by this micrometer is the “pitch diameter” of the

thread and is equal to the outside diameter minus the depth of

one thread. This depth may be determined as follows:

Depth of a V-thread = 0.866 ÷ No. of threads per inch;

Depth of a U. S. standard thread = 0.6495 ÷ No. of threads

per inch;

Depth of Whitworth thread = 0.6403 ÷ No. of threads per inch.

The movable point measures all pitches, but the fixed anvil

is limited in its capacity, for if made large enough to measure a

thread of, say, 1/4-inch pitch, it would be too wide at the top to

measure a thread of 1/24-inch pitch, hence each caliper is limited

in the range of threads that the anvil can measure. When

measuring the “angle diameter” of a thread, the micrometer

should be passed back and forth across the thread, in order to

make sure that the largest dimension or the actual diameter is

being measured. If the micrometer is placed over what seems

to be the center of the screw and the reading is taken by simply

adjusting in the anvil or point against the thread, without moving

the micrometer back and forth across it, an incorrect reading

may be obtained.

Fig. 26. (A) Testing Size of Thread with Ball-point Micrometer.

(B) Testing Size

of V-thread by the Three-wire System.

(C) Testing the Size of a U. S. Standard Thread

If standard threaded reference gages are available, the size

of the thread being cut can be tested by comparing it with the

gage. Micrometers having small spherical measuring ends (see

sketch A, Fig. 26) are sometimes used for this purpose. The

ball points are small enough to bear against the sides of the

thread and the diameter, as compared with the reference gage,

can be determined with great accuracy.

Three-wire System of Measuring Threads.—A method of

measuring threads by using an ordinary micrometer and three

wires of equal diameter is illustrated at B and C, Fig. 26. Two

wires are placed between the threads on one side and one on the

opposite side of the screw. The dimension M over the wires is

then measured with an ordinary micrometer. When the thread

is cut to a standard size, the dimension M for different threads

is as follows:

For a U. S. standard thread:

m = d - 1.5155p + 3w

For a sharp V-thread:

m = d - 1.732p + 3w

For a Whitworth standard thread:

m = d - 1.6008p + 3.1657w

In these formulas, d = standard outside diameter of screw;

m = measurement over wires; w = diameter of wires; p =

pitch of thread = 1 ÷ number of threads per inch.

To illustrate the use of the formula for the U. S. standard

thread, let us assume that a screw having 6 threads per inch

(1/6-inch pitch) is to be cut to a diameter of 11/2

inch, and that wires 0.140 inch diameter are to be used in conjunction

with a micrometer for measurement. Then the micrometer reading m should

be

11/2 - 1.5155 × 1/6 + 3 × 0.140 = 1.6674 inch

If the micrometer reading were 1.670 inch, it would indicate

that the pitch diameter of the screw was too large, the error

being equal to difference between 1.667 and the actual reading.

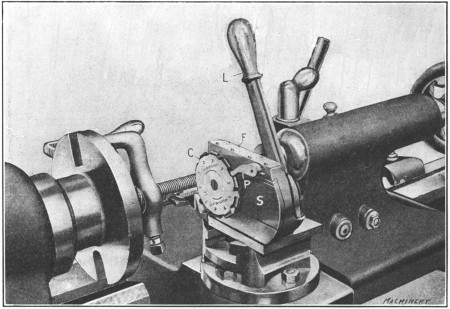

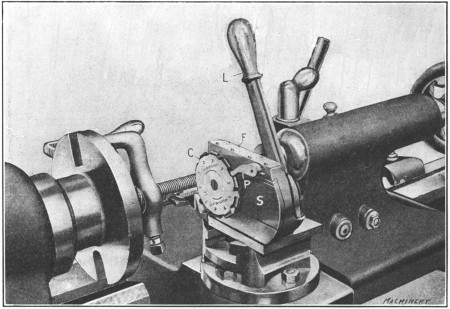

Fig. 27. Rivett-Dock Circular Threading Tool in Working Position

Rivett-Dock Threading Tool.—A special form of thread tool,

which overcomes a number of disadvantages common to an

ordinary single-point thread tool, is shown in Fig. 27. This

tool has a circular-shaped cutter C, having ten teeth around its

circumference, which, beginning with tooth No. 1, gradually increase

in height, cutter No. 2 being higher than No. 1, etc.

This cutter is mounted on a slide S, that is fitted to the frame

F, and can be moved in or out by lever L. The hub of this lever

has an eccentric stud which moves slide S and locks it when

in the forward or cutting position. The action of the lever in

moving the slide engages the cutter with pawl P, thus rotating

the cutter one tooth at a time and presenting a different tooth to the

work for each movement of the lever. When the slide is moved forward,

the heel or underside of the tooth which is in the working position

rests on a stop that takes the thrust of the cut.

When the tool is in use, it is mounted on the tool-block of the

lathe as shown in the illustration. The cutter is set for height

by placing a tooth in the working position and setting the top

level with the lathe center. The cutter is also set square with

the work by using an ordinary square, and it is tilted slightly

from the vertical to correspond with the angle of the thread to

be cut, by adjusting frame F. At first a light cut is taken with

lever L moved forward and tooth No. 1 on the stop. After

this cut is completed, the lever is reversed which rotates the

cutter one tooth, and the return movement places tooth No. 2

in the working position. This operation is repeated until the

tenth tooth finishes the thread. It is often necessary, when

using a single-point thread tool, to re-sharpen it before taking

the finishing cut, but with a circular tool this is not necessary,

for by using the different teeth successively, the last tooth,

which only takes finishing cuts, is kept in good condition.

Cutting Screws to Compensate for Shrinkage.—Some tool

steels are liable to shrink more or less when they are hardened;

consequently if a very accurate hardened screw is required, it is

sometimes cut so that the pitch is slightly greater than standard,

to compensate for the shrinkage due to the hardening

operation. As the amount of contraction incident to hardening

is very little, it is not practicable to use change gears that will

give the exact pitch required. A well-known method of obtaining

this increase of pitch is by the use of a taper attachment.

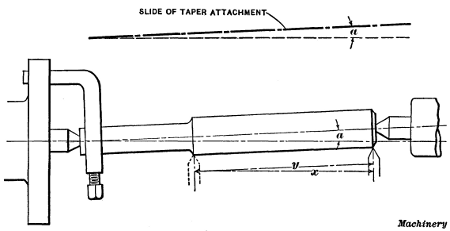

Fig. 28. Diagram Illustrating Method of Cutting a Thread to

Compensate for the Error in Pitch

due to Shrinkage in Hardening

For example, suppose a tap having 8 threads per inch is to be

threaded, and, owing to the contraction of the steel, the pitch

must be 0.12502 inch instead of 0.125 inch. The lathe is geared

to cut 8 threads per inch or 0.125 inch pitch, and then the

taper attachment is set to an angle a, Fig. 28, the cosine of

which equals 0.125÷0.12502; that is, the cosine of angle a equals the

pitch required after hardening, divided by the pitch necessary to

compensate for shrinkage. The angle is then found by referring to a

table of cosines. The tap blank is also set to the same angle a by

adjusting the tailstock center, thus locating the axis of the work

parallel with the slide of the taper attachment. When the carriage moves

a distance x, the tool point will have

moved a greater distance y along the work, the difference between

x and y depending upon angle a; hence the tool will cut

a thread of slightly greater pitch than the lathe is geared to cut.

To illustrate by using the preceding example, cosine of angle

a = 0.125÷0.12502 = 0.99984. By referring to a table of cosines, we

find that 0.99984 is the cosine of 1 degree, approximately;

hence, the taper attachment slide and the work should be set

to this angle. (The angle a in Fig. 28 has been exaggerated in

order to more clearly illustrate the principle.)

As is well known, it is objectionable to cut a thread with the

tailstock center offset, because the work is not rotated at a

uniform velocity, owing to the fact that the driving dog is at an

angle with the faceplate. For a small angle such as 1 degree,

however, the error resulting from this cause would be very

small.

If a thread having a pitch slightly less than standard is needed to

fit a threaded part which has contracted in hardening, the taper

attachment can also be used provided the lathe is equipped with special

gears to cut a little less than the required pitch. Suppose a screw

having a pitch of 0.198 inch is required to fit the thread of a nut the

pitch of which has been reduced from 0.200 inch to 0.198 inch. If gears

having 83 and 84 teeth are available, these can be inserted in a

compound train, so as to reduce the 0.200 inch pitch that would be

obtained with the regular gearing, to 83/84 of 0.200 or 0.19762 inch.

This pitch, which is less than the 0.198 inch pitch required, is

then increased by using the taper attachment as previously described.

(This method was described by Mr. G. H. Gardner

in Machinery, February, 1914.)

Calculating Change Gears for Thread Cutting.—As previously

mentioned, the change gears for cutting threads of various

pitches are shown by a table or “index plate” attached to

the lathe. The proper gears to be used can be calculated, but

the use of the table saves time and tends to avoid mistakes.

Every machinist, however, should know how to determine the

size of gears used for cutting any number of threads to the

inch. Before referring to any rules, let us first consider why a

lathe cuts a certain number of threads to the inch and how this

number is changed by the use of different gears.

Fig. 29. (A) Lathe with Simple Gearing for Thread Cutting.

(B) Compound Geared Lathe

As the carriage C and the tool are moved by the lead-screw

S (see Fig. 2), which is geared to the spindle, the number of

threads to the inch that are cut depends, in every case, upon the

number of turns the work makes while the lead-screw is moving

the carriage one inch. If the lead-screw has six threads per

inch, it will make six revolutions while the carriage and the

thread tool travel one inch along the piece to be threaded.

Now if the change gears a and c (see also sketch A, Fig. 29) are

so proportioned that the spindle makes the same number of

revolutions as the lead-screw, in a given time, it is evident that

the tool will cut six threads per inch. If the spindle revolved

twice as fast as the lead-screw, it would make twelve turns

while the tool moved one inch, and, consequently, twelve threads

per inch would be cut; but to get this difference in speeds it is

necessary to use a combination of gearing that will cause the

lead-screw to revolve once while the lathe spindle and work

make two revolutions.

Suppose that nine threads to the inch are to be cut and the

lead-screw has six threads per inch. In this case the work must

make nine revolutions while the lead-screw makes six and causes

the carriage and thread tool to move one inch, or in other words,

one revolution of the lead-screw corresponds to one and one-half

revolution of the spindle; therefore, if the lead-screw gear

c has 36 teeth, the gear a on the spindle stud should have

24 teeth. The spindle will then revolve one and one-half times faster

than the lead-screw, provided the stud rotates at the same rate of speed

as the main lathe spindle. The number of teeth in the change gears that

is required for a certain pitch can be found by multiplying the number

of threads per inch of the lead-screw, and the number of threads per

inch to be cut, by the same trial multiplier. The formula which

expresses the relation between threads per inch of lead-screw, threads

per inch to be cut, and the number of teeth in the change gears, is as

follows:

Applying this to the example given, we have 6÷9 = 24÷36. The

values of 36 and 24 are obtained by multiplying 6 and 9, respectively,

by 4, which, of course, does not change the proportion.

Any other number could be used as a multiplier, and if gears

having 24 and 36 teeth were not available, this might be necessary.

For example, if there were no gears of this size, some

other multiplier as 5 or 6 might be used.

Suppose the number of teeth in the change gears supplied

with the lathe are 24, 28, 32, 36, etc., increasing by four teeth

up to 100, and assume that the lead-screw has 6 threads per

inch and that 10 threads per inch are to be cut. Then,

By multiplying both numerator and denominator by 4, we

obtain two available gears having 24 and 40 teeth, respectively.

The 24-tooth gear goes on the spindle stud and, the 40-tooth gear

on the lead-screw. The number of teeth in the intermediate or

“idler” gear b, which connects the stud and lead-screw gears, is

not considered as it does not affect the ratios between gears a

and c, but is used simply to transmit motion from one gear to

the other.

We have assumed in the foregoing that the spindle stud (on

which gear a is mounted) and the main spindle of the lathe are

geared in the ratio of one to one and make the same number of

revolutions. In some lathes, however, these two members do not rotate at

the same speed, so that if equal gears were placed on the lead-screw

and spindle stud, the spindle would not make the same number of

revolutions as the lead-screw. In that case if the actual number of

threads per inch in the lead-screw were used when calculating the change

gears, the result would be incorrect; hence, to avoid mistakes, the

following general rule should be used as it gives the correct result,

regardless of the ratios of the gears which connect the spindle and

spindle stud:

Rule.—First find the number of threads per inch that is cut

when gears of the same size are placed on the lead-screw and spindle,

either by actual trial or by referring to the index plate. Then

place this number as the numerator of a fraction and the number

of threads per inch to be cut, as the denominator; multiply both

numerator and denominator by some trial number, until numbers

are obtained which correspond to numbers of teeth in gears that are

available. The product of the trial number and the numerator

(or “lathe screw constant”) represents the gear a for the spindle

stud, and the product of the trial number and the denominator,

the gear for the lead-screw.

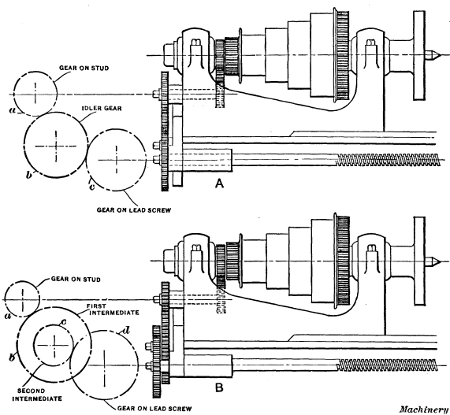

Lathes with Compound Gearing.—When gearing is arranged

as shown at A, Fig. 29, it is referred to as simple gearing, but

sometimes it is necessary to introduce two gears between the

stud and screw as at B, which is termed compound gearing.

The method of figuring compound gearing is practically the same

as that for simple gearing. To find the change gears used in

compound gearing, place the “screw constant” obtained by the

foregoing rule, as the numerator, and the number of threads per

inch to be cut as the denominator of a fraction; resolve both

numerator and denominator into two factors each, and multiply

each “pair” of factors by the same number, until values are

obtained representing numbers of teeth in available change

gears. (One factor in the numerator and one in the denominator

make a “pair” of factors.)

Suppose the lathe cuts 6 threads per inch when gears of equal

size are used, and that the number of teeth in the gears available

are 30, 35, 40 and so on, increasing by 5 up to 100. If 24

threads per inch are to be cut, the screw constant 6 is placed in

the numerator and 24 in the denominator. The numerator and

denominator are then divided into factors and each pair of

factors is multiplied by the same number to find the gears,

thus:

The last four numbers indicate the gears which should be used.

The upper two having 40 and 30 teeth are the driving gears

and the lower two having 80 and 60 teeth are the driven gears.

The driving gears are gear a on the spindle stud and gear c on

the intermediate stud, meshing with the lead-screw gear, and

the driven gears are gears b and d. It makes no difference which

of the driving gears is placed on the spindle stud, or which of

the driven is placed on the lead-screw.

Fractional Threads.—Sometimes the lead of a thread is

given as a fraction of an inch instead of stating the number

of threads per inch. For example, a thread may be required

to be cut, having 3/8-inch lead. The expression “3/8-inch lead”

should first be transformed to “number of threads per inch.”

The number of threads per inch (the thread being single) equals:

To find the change gears to cut 22/3 threads per inch in a lathe

having a screw constant of 8 and change gears varying from 24

to 100 teeth, increasing by 4, proceed as follows:

As another illustration, suppose we are to cut 13/4 thread per

inch on a lathe having a screw constant of 8, and that the gears

have 24, 28, 32, 36, 40 teeth, etc., increasing by four up to one

hundred. Following the rule:

The gears having 72 and 64 teeth are the driving gears, and

those with 36 and 28 teeth are the driven gears.

Change Gears for Metric Pitches.—When

screws are cut in accordance with the metric system, it is the usual

practice to give the lead of the thread in millimeters, instead of the

number of threads per unit of measurement. To find the change gears for

cutting metric threads, when using a lathe having an English lead-screw,

first determine the number of threads per inch

corresponding to the given lead in millimeters. Suppose a thread of 3

millimeters lead is to be cut in a lathe having an English lead-screw

and a screw constant of 6. As there are 25.4 millimeters per inch, the

number of threads per inch will equal 25.4 ÷ 3. Place the

screw constant as the numerator, and the number of threads per inch to

be cut as the denominator:

The numerator and denominator of this fractional expression

of the change-gear ratio are next multiplied by some trial number

to determine the size of the gears. The first whole number

by which 25.4 can be multiplied so as to get a whole number as

the result is 5. Thus, 25.4 × 5 = 127; hence, one gear having

127 teeth is always used when cutting metric threads with

an English lead-screw. The other gear required in this case

has 90 teeth. Thus:

Therefore, the following rule can be used to find the change

gears for cutting metric pitches with an English lead-screw:

Rule.—Place the lathe screw constant multiplied by the lead of

the required thread in millimeters multiplied by 5, as the numerator

of the fraction, and 127 as the denominator. The product of the

numbers in the numerator equals the number of teeth for the spindle-stud

gear, and 127 is the number of teeth for the lead-screw gear.

If the lathe has a metric pitch lead-screw, and a screw having

a given number of threads per inch is to be cut, first find the

“metric screw constant” of the lathe or the lead of thread in

millimeters that would be cut with change gears of equal size

on the lead-screw and spindle stud; then the method of determining

the change gears is simply the reverse of the one already

explained for cutting a metric thread with an English lead-screw.

Rule.—To find the change gears for cutting English threads

with a metric lead-screw, place 127 in the numerator and the threads

per inch to be cut, multiplied by the metric screw constant multiplied

by 5, in the denominator; 127 is the number of teeth on the

spindle-stud gear and the product of the numbers in the denominator

equals the number of teeth in the lead-screw gear.

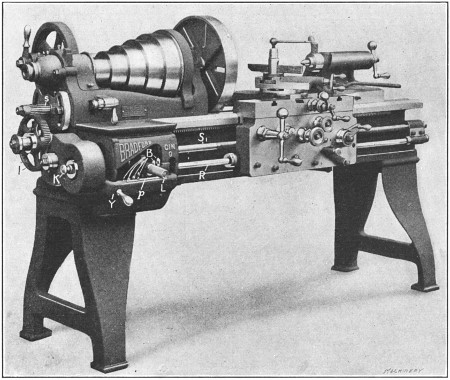

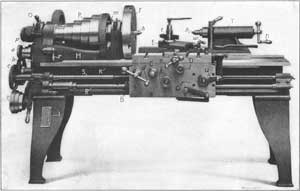

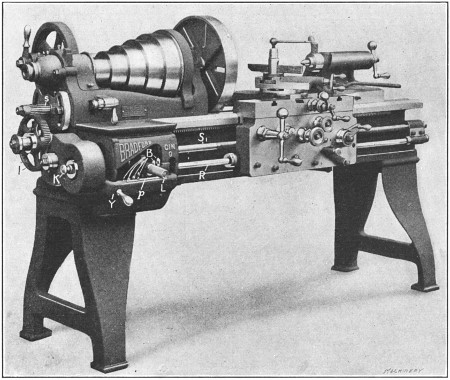

Fig. 30. Lathe having Quick Change-gear Mechanism

Quick Change-gear Type of Lathe.—A type of lathe that is

much used at the present time is shown in Fig. 30. This is

known as the quick change-gear type, because it has a system

of gearing which makes it unnecessary to remove the change

gears and replace them with different sizes for cutting threads

of various pitches. Changes of feed are also obtained by the

same mechanism, but the feeding movement is transmitted to

the carriage by the rod R, whereas the screw S1 is used for screw

cutting. As previously explained, the idea of using the screw exclusively

for threading is to prevent it from being worn excessively,

as it would be if continually used in place of rod R, for

feeding the carriage when turning.

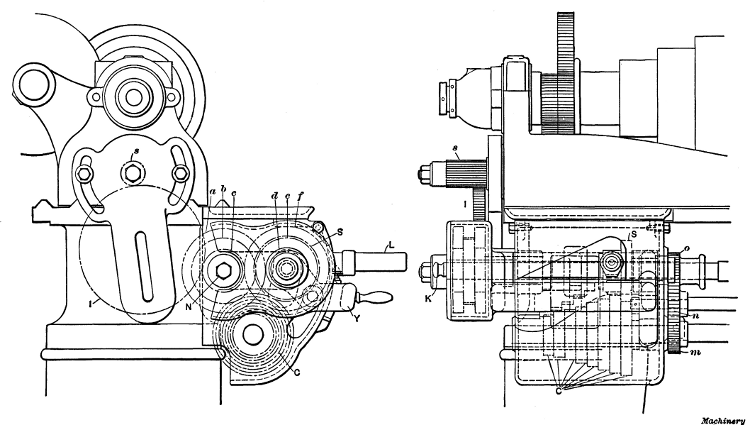

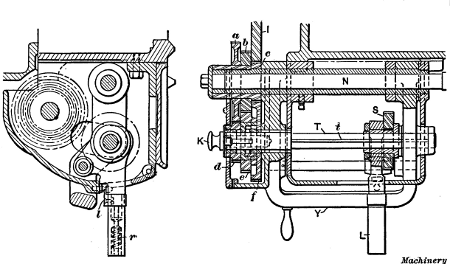

Fig. 31. End and Side Views of Quick Change-gear Mechanism

The general construction of this quick change gear mechanism and the

way the changes are made for cutting threads of different pitch, will be

explained in connection with Figs. 30, 31 and

32, which are marked with the same reference letters for corresponding

parts. Referring to Fig. 30, the movement is transmitted

from gear s on the spindle stud through idler gear I,

which can be moved sidewise to mesh with either of the three

gears a, b or c, Fig. 31. This cone of three gears engages gears

d, e and f, any one of which can be locked with shaft T (Fig.

32) by changing the position of knob K. On shaft T there is

a gear S which can be moved along the shaft by hand lever L

and, owing to the spline or key t, both the sliding gear and shaft

rotate together. Shaft T, carrying gears d, e and f and the

sliding gear S, is mounted in a yoke Y, which can be turned

about shaft N, thus making it possible to lower sliding gear S

into mesh with any one of a cone of eight gears C, Fig. 31. The

shaft on which the eight gears are mounted has at the end a

small gear m meshing with gear n on the feed-rod, and the latter,

in turn, drives the lead-screw, unless gear o is shifted to the

right out of engagement, which is its position except when

cutting threads.

Fig. 32. Sectional Views of Quick Change-gear Mechanism

With this mechanism, eight changes for different threads or

feeds are obtained by simply placing gear S into mesh with the various sized gears in cone C. As the speed of shaft T depends

on which of the three gears d, e and f are locked to it, the eight

changes are tripled by changing the position of knob K, making

twenty-four. Now by shifting idler gear I, three speed changes

may be obtained for gears a, b and c, which rotate together, so

that the twenty-four changes are also tripled, giving a total of

seventy-two variations without

removing any gears, and if a

different sized gear s were placed

on the spindle stud, an entirely

different range could be obtained,

but such a change would

rarely be necessary. As shown

in Fig. 30, there are eight hardened

steel buttons B, or one for

each gear of the cone C, placed

at different heights in the casing.

When lever L is shifted sidewise

to change the position of sliding

gear S, it is lowered onto one

of these buttons (which enters a

pocket on the under side) and in

this way gear S is brought into

proper mesh with any gear of the

cone C. To shift lever L, the

handle is pulled outward against

the tension of spring r (Fig. 32),

which disengages latch l and enables

the lever to be lifted clear of the button; yoke Y is then

raised or lowered, as the case may be, and lever L with the

sliding gear is shifted laterally to the required position.

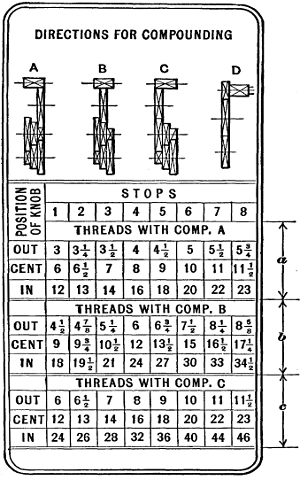

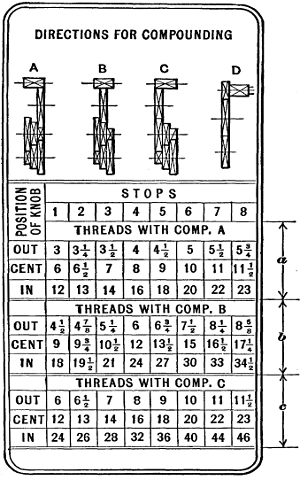

Fig. 33. Index Plate showing Position of Control Levers

for Cutting Threads of Different Pitch

The position of lever L and knob K for cutting threads of

different pitches is shown by an index plate or table attached

to the lathe and arranged as shown in Fig. 33. The upper

section a of this table shows the different numbers of threads to

the inch that can be obtained when idler gear I is in the position

shown by the diagram A. Section b gives the changes when the idler gear is moved, as shown at B, and, similarly, section

c gives the changes for position C of the idler. The horizontal

row of figures from 1 to 8 below the word “stops” represents

the eight positions for lever L, which has a plate p (Fig. 30) just

beneath it with corresponding numbers, and the column to the

left shows whether knob K should be out, in a central position,

or in.

In order to find what the position of lever L and knob K

should be for cutting any given number of threads to the inch,

find what “stop” number is directly above the number of threads

to be cut, which will indicate the location of lever L, and also what

position should be occupied by knob K, as shown in the column

to the left. For example, suppose the lathe is to be geared for

cutting eight threads to the inch. By referring to section a we

see that lever L should be in position 4 and knob K in the center,

provided the idler gear I were in position A, as it would be

ordinarily, because all standard numbers of threads per inch

(U. S. standard) from 1/4 inch up to and including 4 inches in

diameter can be cut with the idler gear in that position. As

another illustration, suppose we want to cut twenty-eight threads

per inch. This is listed in section c, which shows that lever L

must be placed in position 3 with knob K pushed in and the

idler gear shifted to the left as at C.

The simplicity of this method as compared with the time-consuming

operation of removing and changing gears is apparent.

The diagram D to the right shows an arrangement of

gearing for cutting nineteen threads per inch. A 20-tooth gear

is placed on the spindle stud (in place of the regular one having

16 teeth) and one with 95 teeth on the lead-screw, thus driving

the latter direct as with ordinary change gears. Of course it

will be understood that the arrangement of a quick change-gear

mechanism varies somewhat on lathes of different make.

Return to Contents