|

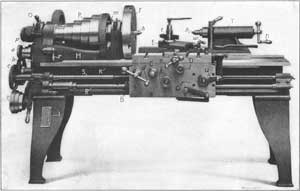

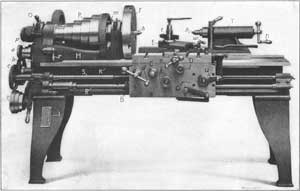

Turning and Boring on a Lathe

Online Reprint Chapter 2

This a complete book, published in

1914, divided into chapters on how to use a metal lathe, covering all

turning and boring operations.

|

Return to Contents

Turning and Boring

by Franklin D. Jones

Published by Industrial Press 1914

A special treatise for machinists students in industrial and

engineering schools, and apprentices on turning and boring methods

including modern practice with engine lathes, vertical, and horizontal

boring machines.

Shop Amazon.com

|

CHAPTER II

LATHE TURNING TOOLS AND CUTTING SPEEDS

Notwithstanding the fact that a great variety of work can

be done in the lathe, the number of turning tools required is

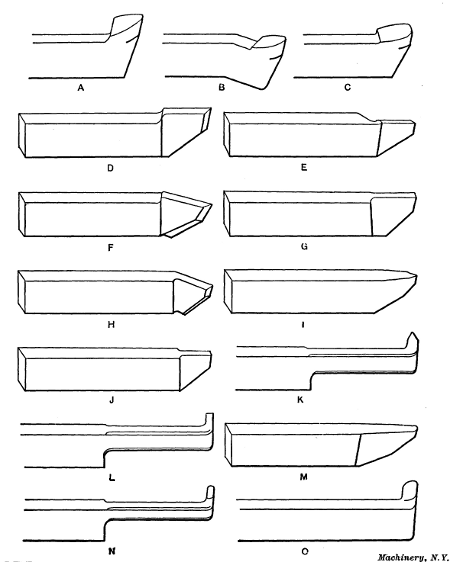

comparatively small. Fig. 1 shows the forms of tools that are

used principally, and typical examples of the application of

these various tools are indicated in Fig. 2. The reference letters

used in these two illustrations correspond for tools of the same

type, and both views should be referred to in connection with

the following description.

Fig. 1. Set of Lathe Turning Tools for General Work

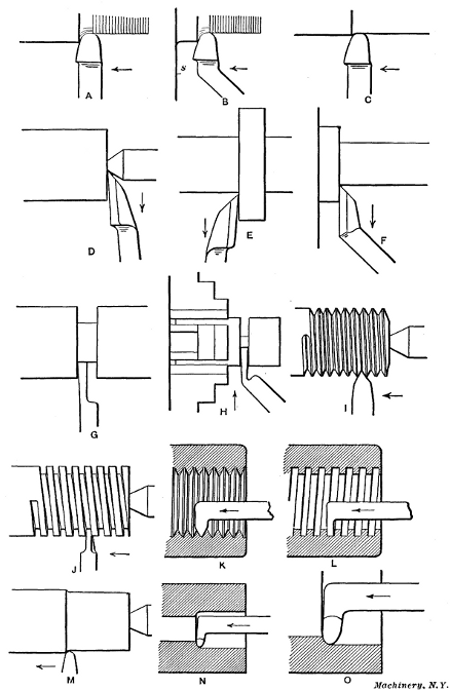

Fig. 2. Views illustrating Use of Various Types of Lathe Tools

Turning Tools for General Work.—The tool shown at A is

the form generally used for rough turning, that is for taking

deep cuts when considerable metal has to be removed. At B a

tool of the same type is shown, having a bent end which enables

it to be used close up to a shoulder or surface s that might come

in contact with the tool-rest if the straight form were employed.

Tool C, which has a straight cutting end, is used on certain

classes of work for taking light finishing cuts, with a coarse

feed. This type of tool has a flat or straight cutting edge at

the end, and will leave a smooth finish even though the feed is

coarse, provided the cutting edge is set parallel with the tool's

travel so as to avoid ridges. Broad-nosed tools and wide feeds

are better adapted for finishing cast iron than steel. When

turning steel, if the work is at all flexible, a broad tool tends to

gouge into it and for this reason round-nosed tools and finer

feeds are generally necessary. A little experience in turning

will teach more on this point than a whole chapter on the subject.

The side-tools shown at D and E are for facing the ends of

shafts, collars, etc. The first tool is known as a right side-tool

because it operates on the right end or side of a shaft or collar,

whereas the left side-tool E is used on the opposite side, as shown

in Fig. 2. Side-tools are also bent to the right

or left because the cutting edge of a straight tool cannot always be

located properly for facing certain surfaces. A bent right side-tool is

shown at F. A form of tool that is frequently used is shown at

G; this is known as a parting tool and is used for severing pieces

and for cutting grooves, squaring corners, etc. The same type

of tool having a bent end is shown at H (Fig. 2)

severing a piece held in the chuck. Work that is held between centers

should not be entirely severed with a parting tool unless a steadyrest

is placed between the tool and faceplate, as otherwise the tool may be

broken by the springing of the work just before the piece is cut in two.

It should be noted that the sides of this tool slope inward back of the

cutting edge to provide clearance when cutting in a narrow groove.

At I a thread tool is shown for cutting a U. S. standard thread.

This thread is the form most commonly used in this country at

the present time. A tool for cutting a square thread is shown

at J. This is shaped very much like a parting tool except that

the cutting end is inclined slightly to correspond with the helix

angle of the thread, as explained in Chapter IV, which contains

descriptions of different thread forms and methods of cutting

them. Internal thread tools are shown at K and L for cutting

U. S. standard and square threads in holes. It will be seen

that these tools are somewhat like boring tools excepting the

ends which are shaped to correspond with the thread which

they are intended to cut.

A tool for turning brass is shown at M. Brass tools intended

for general work are drawn out quite thin and they are given a

narrow rounded point. The top of the brass tool is usually

ground flat or without slope as otherwise it tends to gouge into

the work, especially if the latter is at all flexible. The end of a

brass tool is sometimes ground with a straight cutting edge for

turning large rigid work, such as brass pump linings, etc., so

that a coarse feed can be used without leaving a rough surface.

The tools at N and O are for boring or finishing drilled or cored

holes. Two sizes are shown, which are intended for small and

large holes, respectively.

The different tools referred to in the foregoing might be called

the standard types because they are the ones generally used,

and as Fig. 2 indicates, they make it possible to

turn an almost endless variety of forms. Occasionally some special form

of tool is needed for doing odd jobs, having, perhaps, an end bent

differently or a cutting edge shaped to some particular form. Tools of

the latter type, which are known as “form tools,” are sometimes used for

finishing surfaces that are either convex, concave, or irregular in

shape. The cutting edges of these tools are carefully filed or ground to

the required shape, and the form given the tool is reproduced in the

part turned. Ornamental or other irregular surfaces can be finished very

neatly by the use of such tools. It is very difficult, of course, to

turn convex or concave surfaces with a regular tool; in fact, it would

not be possible to form a true spherical surface, for instance, without

special equipment, because the tool could not be moved along a true

curve by simply using the longitudinal and cross feeds. Form tools

should be sharpened by grinding entirely on the top surface, as any

grinding on the end or flank would alter the shape of the tool.

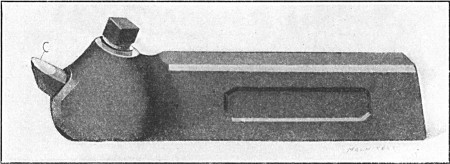

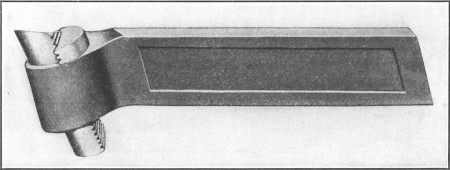

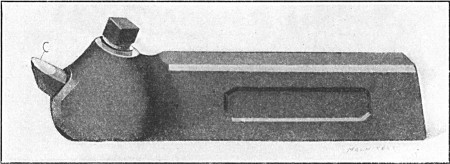

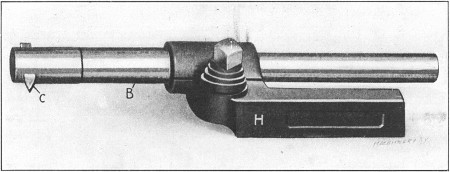

Fig. 3. Turning Tool with Inserted Cutter

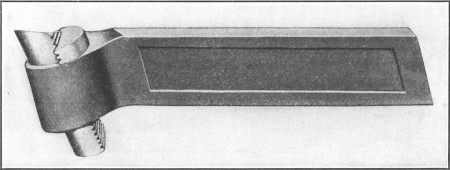

Fig. 4. Heavy Inserted-cutter Turning Tool

Tool-holders with Inserted Cutters.—All of the tools shown

in Fig. 1 are forged from the bar, and when the cutting ends

have been ground down considerably it is necessary to forge a

new end. To eliminate the expense of this continual dressing of

tools and also to effect a great reduction in the amount of tool

steel required, tool-holders having small inserted cutters are

used in many shops. A tool-holder of this type, for outside

turning, is shown in Fig. 3. The cutter C

is held in a fixed position by the set-screw shown, and it is sharpened,

principally, by grinding the end, except when it is desired to give the

top of the cutter a different slope from that due to its angular

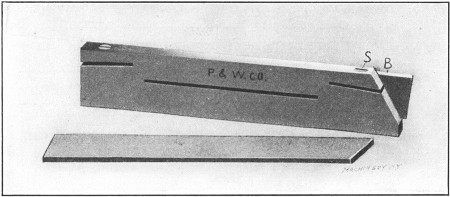

position. Another inserted-cutter turning tool is shown in Fig. 4, which

is a heavy type intended for roughing. The cutter in this case

has teeth on the rear side engaging with corresponding teeth

cut in the clamping block which is tightened by a set-screw on

the side opposite that shown. With this arrangement, the cutter

can be adjusted upward as the top is ground away.

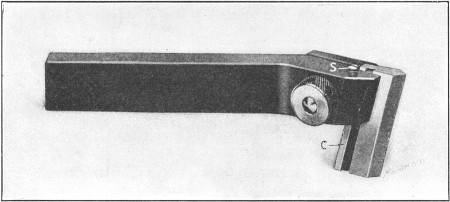

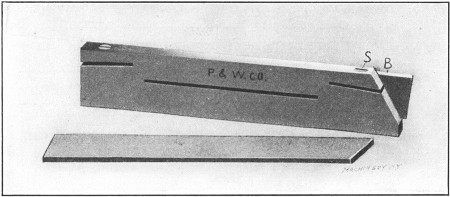

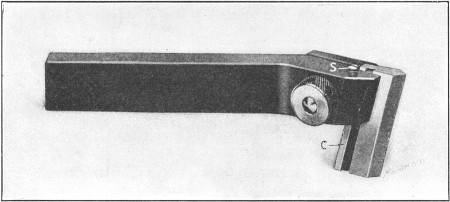

Fig. 5. Parting Tool with Inserted Blade

Fig. 6. Boring Tool with Inserted Cutter and Adjustable Bar

Fig. 7. Threading Tool

A parting tool of the inserted blade type is shown in Fig. 5.

The blade B is clamped by screw S and also by the spring of

the holder when the latter is clamped in the toolpost. The

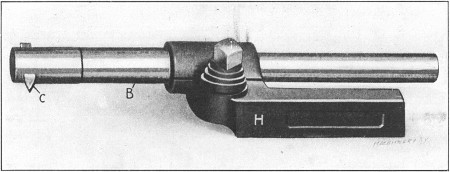

blade can, of course, be moved outward when necessary. Fig. 6

shows a boring tool consisting of a holder H, a bar B that can

be clamped in any position, and an inserted cutter C. With this

type of boring tool, the bar can be extended beyond the holder

just far enough to reach through the hole to be bored, which

makes the tool very rigid. A thread tool of the holder type is

shown in Fig. 7. The angular edge of the cutter C

is accurately ground by the manufacturers, so that the tool is

sharpened by simply grinding it flat on the top. As the top is ground

away, the cutter is raised by turning screw S, which can also be used

for setting the tool to the proper height.

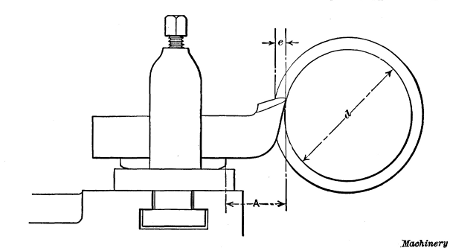

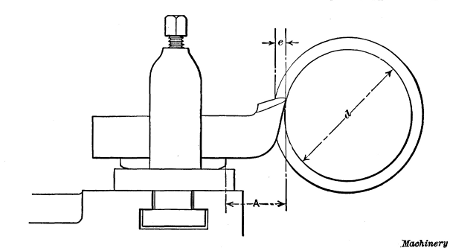

Fig. 8. To avoid springing, Overhang A of Tool should not be Excessive

The Position of Turning Tools.—The production of accurate

lathe work depends partly on the condition of the lathe used

and also on the care and judgment exercised by the man operating

it. Even though a lathe is properly adjusted and in good

condition otherwise, errors are often made which are due to

other causes which should be carefully avoided. If the turning

tool is clamped so that the cutting end extends too far from the

supporting block, the downward spring of the tool, owing to

the thrust of the cut, sometimes results in spoiled work, especially

when an attempt is made to turn close to the finished

size by taking a heavy roughing cut. Suppose the end of a

cylindrical part is first reduced for a short distance by taking

several trial cuts until the diameter d, Fig. 8, is slightly above

the finished size and the power feed is then engaged. When

the tool begins to take the full depth e of the cut, the point,

which ordinarily would be set a little above the center, tends to

spring downward into the work, and if there were considerable

springing action, the part would probably be turned below the

finished size, the increased reduction beginning at the point

where the full cut started.

This springing action, as far as the tool is concerned, can be practically eliminated by locating the tool so that the distance A between the tool-block and cutting end, or the “overhang,”

is as short as possible. Even though the tool has little overhang

it may tilt downward because the toolslide is loose on its ways,

and for this reason the slide should have a snug adjustment

that will permit an easy movement without unnecessary play.

The toolslides of all lathes are provided with gibs which can

be adjusted by screws to compensate for wear, or to secure a

more rigid bearing.

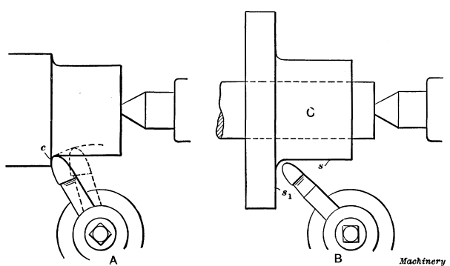

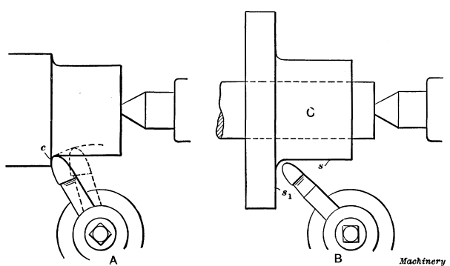

Fig. 9. (A) The Way in which Tool is sometimes displaced by Thrust of Cut,

when set at an Angle.

(B) Tool Set for Finishing both Cylindrical and

Radial Surfaces

When roughing cuts are to be taken, the tool should be located

so that any change in its position which might be caused by the

pressure of the cut will not spoil the work. This point is illustrated

at A in Fig. 9. Suppose the end of a rod has been reduced

by taking a number of trial cuts, until it is 1/32 inch above the

finished size. If the power feed is then engaged with the tool

clamped in an oblique position, as shown, when the full cut is

encountered at c, the tool, unless very tightly clamped, may be

shifted backward by the lateral thrust of the cut, as indicated by the

dotted lines. The point will then begin turning smaller than the

finished size and the work will be spoiled. To prevent any change of

position, it is good practice, especially when roughing, to clamp the

tool square with the surface being turned, or in other words, at right

angles to its direction of movement. Occasionally, however, there is a

decided advantage in having the tool set at an angle. For example, if it

is held about as shown at B, when turning the flange casting C, the surfaces s

and s1 can be finished without changing the tool's position.

Cylindrical and radial surfaces are often turned in this way

in order to avoid shifting the tool, especially when machining

parts in quantity.

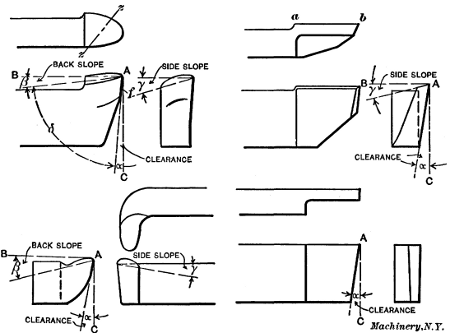

Tool Grinding.—In the grinding of lathe tools there are

three things of importance to be considered: First, the cutting

edge of the tool (as viewed from the top) needs to be given a

certain shape; second, there must be a sufficient amount of

clearance for the cutting edge; and third, tools, with certain

exceptions, are ground with a backward slope or a side slope,

or with a combination of these two slopes on that part against

which the chip bears when the tool is in use.

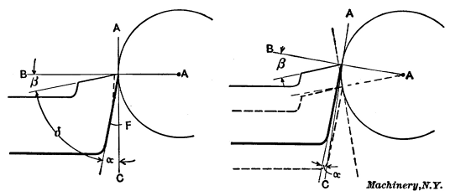

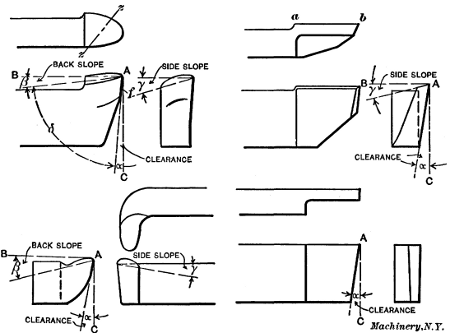

Fig. 10. Illustration showing the Meaning of Terms used

in Tool

Grinding as applied to Tools of Different Types

In Fig. 10 a few of the different types of tools which are used

in connection with lathe work are shown. This illustration also

indicates the meaning of the various terms used in tool grinding.

As shown, the clearance of the tool is represented by the

angle α, the back slope is represented by the angle β, and the

side slope by the angle γ. The angle δ for a tool without

side slope is known as the lip angle or the angle of keenness. When,

however, the tool has both back and side slopes, this lip angle would

more properly be the angle between the flank f and the

top of the tool, measured diagonally along a line z—z. It will

be seen that the lines A—B and A—C from which the angles

of clearance and back slope are measured are parallel with the

top and sides of the tool shank, respectively. For lathe tools,

however, these lines are not necessarily located in this way

when the tool is in use, as the height of the tool point with

relation to the work center determines the position of these

lines, so that the effective angles of back slope, clearance and

keenness are changed as the tool point is lowered or raised.

The way the position of the tool affects these angles will be

explained later.

While tools must, of necessity, be varied considerably in shape to

adapt them to various purposes, there are certain underlying principles

governing their shape which apply generally; so in what follows we shall

not attempt to explain in detail just what the form of each tool used

on the lathe should be, as it is more important to understand how the

cutting action of the tool and its efficiency is affected when it is

improperly ground.When the principle is understood, the grinding of

tools of various types and shapes is comparatively easy.

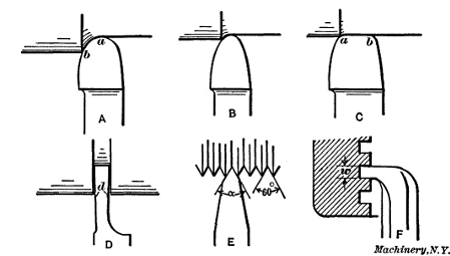

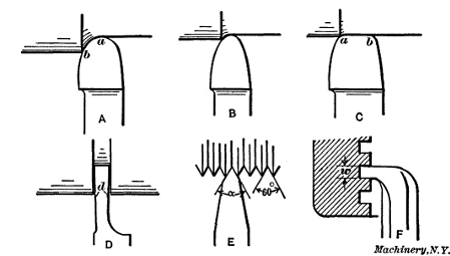

Fig. 11. Plan View of Lathe Turning and Threading Tools

Shape or Contour of Cutting Edge.—In the first place we

shall consider the shape or contour of the cutting edge of the

tool as viewed from the top, and then take up the question of

clearance and slope, the different elements being considered

separately to avoid confusion. The contour of the cutting edge

depends primarily upon the purpose for which the tool is intended.

For example, the tool A, in Fig. 11, where a plan view

of a number of different lathe tools is shown, has a very different

shape from that of, say, tool D, as the first tool is used for rough

turning, while tool D is intended for cutting grooves or severing

a turned part. Similarly, tool E is V-shaped because it is used

for cutting V-threads. Tools A, B and C, however, are regular

turning tools; that is, they are all intended for turning plain

cylindrical surfaces, but the contour of the cutting edges varies

considerably, as shown. In this case it is the characteristics of

the work and the cut that are the factors which determine the

shape. To illustrate, tool A is of a shape suitable for rough-turning

large and rigid work, while tool B is adapted for smaller

and more flexible parts. The first tool is well shaped for roughing

because experiments have shown that a cutting edge of a

large radius is capable of higher cutting speed than could be

used with a tool like B, which has a smaller point. This increase

in the cutting speed is due to the fact that the tool A

removes a thinner chip for a given feed than tool B; therefore,

the speed may be increased without injuring the cutting edge

to the same extent. If, however, tool A were to be used for

turning a long and flexible part, chattering might result; consequently,

a tool B having a point with a smaller radius would

be preferable, if not absolutely necessary.

The character of the work also affects the shape of tools.

The tool shown at C is used for taking light finishing cuts with

a wide feed. Obviously, if the straight or flat part of the cutting

edge is in line with the travel of the tool, the cut will be smooth

and free from ridges, even though the feed is coarse, and by

using a coarse feed the cut is taken in less time; but such a

tool cannot be used on work that is not rigid, as chattering

would result. Therefore, a smaller cutting point and a reduced

feed would have to be employed. Tools with broad flat cutting

edges and coarse feeds are often used for taking finishing cuts

in cast iron, as this metal offers less resistance to cutting than

steel, and is less conducive to chattering.

The shape of a tool (as viewed from the top) which is intended

for a more specific purpose than regular turning, can be largely

determined by simply considering the tool under working conditions.

This point may be illustrated by the parting tool D

which, as previously stated, is used for cutting grooves, squaring

corners, etc. Evidently this tool should be widest at the

cutting edge; that is, the sides d should have a slight amount

of clearance so that they will not bind as the tool is fed into a

groove. As the tool at E is for cutting a V-thread, the angle α

between its cutting edges must equal the angle between the

sides of a V-thread, or 60 degrees. The tool illustrated at F is

for cutting inside square threads. In this case the width w

should be made equal to one-half the pitch of the thread (or

slightly greater to provide clearance for the screw), and the

sides should be given a slight amount of side clearance, the

same as with the parting tool D. So we see that the outline of

the tool, as viewed from the top, must conform to and be governed

by its use.

Direction of Top Slope for Turning Tools.—Aside from the

question of the shape of the cutting edge as viewed from the

top, there remains to be determined the amount of clearance

that the tool shall have, and also the slope (and its direction) of

the top of the tool. By the top is meant that surface against

which the chip bears while it is being severed. It may be stated,

in a general way, that the direction in which the top of the tool

should slope should be away from what is to be the working

part of the cutting edge. For example, the working edge of a

roughing tool A (Fig. 11), which is used for heavy cuts, would

be, practically speaking, between points a and b, or, in other

words, most of the work would be done by this part of the cutting

edge; therefore the top should slope back from this part

of the edge. Obviously, a tool ground in this way will have

both a back and a side slope.

When most of the work is done on the point or nose of the

tool, as, for example, with the lathe finishing tool C which takes

light cuts, the slope should be straight back from the point or

cutting edge a—b. As the side tool shown in Fig. 10 does its

cutting along the edge a—b, the top is given a slope back from

this edge as shown in the end view. This point should be

remembered, for when the top slopes in the right direction, less

power is required for cutting. Tools for certain classes of work,

such as thread tools, or those for turning brass or chilled iron,

are ground flat on top, that is, without back or side slope.

Clearance for the Cutting Edge.—In order that the cutting

edge may work without interference, it must have clearance;

that is, the flank f (Fig. 10) must be ground to a certain angle α

so that it will not rub against the work and prevent the cutting

edge from entering the metal. This clearance should be just

enough to permit the tool to cut freely. A clearance angle of

eight or ten degrees is about right for lathe turning tools.

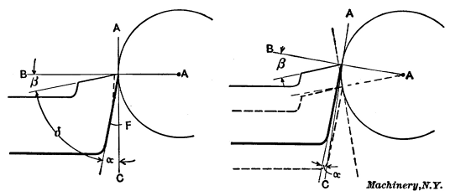

Fig. 12. Illustrations showing how Effective Angles of Slope

and

Clearance change as Tool is raised or lowered

The back slope of a tool is measured from a line A—B which is

parallel to the shank, and the clearance angle, from a line A—C

at right angles to line A—B. These lines do not, however, always

occupy this position with relation to the tool shank when

the tool is in use. As shown to the left in Fig. 12, the base line A—B for a turning tool in use intersects with the point of the

tool and center of the work, while the line A—C remains at right

angles to the first. It will be seen, then, that by raising the

tool, as shown to the right, the effective clearance angle α will

be diminished, whereas lowering it, as shown by the dotted

lines, will have the opposite effect.

A turning tool for brass or other soft metal, particularly

where considerable hand manipulation is required, could advantageously

have a clearance of twelve or fourteen degrees,

as it would then be easier to feed the tool into the metal; but,

generally speaking, the clearance for turning tools should be

just enough to permit them to cut freely. Excessive clearance

weakens the cutting edge and may cause it to crumble under

the pressure of the cut.

Angle of Tool-point and Amount of Top Slope.—The lip

angle or the angle of keenness δ (Fig. 10) is another important

consideration in connection with tool grinding, for it is upon

this angle that the efficiency of the tool largely depends. By

referring to the illustration it will be seen that this angle is

governed by the clearance and the slope β, and as the clearance

remains practically the same, it is the slope which is varied to meet

different conditions. Now, the amount of slope a tool should have

depends on the work for which it is intended. If, for example, a turning

tool is to be used for roughing medium or soft steel, it should have a

back slope of about eight degrees and a side slope ranging from fourteen

to twenty degrees, while a tool for cutting very hard steel should

have a back slope of about five degrees and a side slope of nine

degrees.

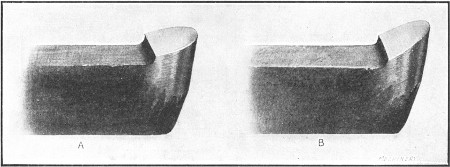

Fig. 13. (A) Blunt Tool for Turning Hard Steel.

(B) Tool-point

Ground to give Keenness

The reason for decreasing the slope and thus increasing the

lip angle for harder metals is to give the necessary increased

strength to the cutting edge to prevent it from crumbling under

the pressure of the cut. The tool illustrated at A, Fig. 13, is

much stronger than it would be if ground as shown at B, as

the former is more blunt. If a tool ground as at A, however,

were used for cutting very soft steel, there would be a greater

chip pressure on the top and, consequently, a greater resistance

to cutting, than if a keener tool had been employed; furthermore

the cutting speed would have to be lower, which is of

even greater importance than the chip pressure; therefore, the

lip angle, as a general rule, should be as small as possible without

weakening the tool so that it cannot do the required work.

In order to secure a strong and well-supported cutting edge,

tools used for turning very hard metal, such as chilled rolls,

etc., are ground with practically no slope and with very little

clearance. Brass tools, while given considerable clearance, as

previously stated, are ground flat on top or without slope; this

is not done, however, to give strength to the cutting edge, but

rather to prevent the tool from gouging into the work, which it

is likely to do if the part being turned is at all flexible and the

tool has top slope.

Experiments conducted by Mr. F. W. Taylor to determine the most

efficient form for lathe roughing tools showed that the nearer the lip

angle approached sixty-one degrees, the higher the cutting speed. This,

however, does not apply to tools for turning cast iron, as the latter

will work more efficiently with a lip angle of about sixty-eight

degrees. This is doubtless because the chip pressure, when turning cast

iron, comes closer to the cutting edge which should, therefore, be more

blunt to withstand the abrasive action and heat. Of course, the

foregoing remarks concerning lip angles apply more particularly to tools

used for roughing.

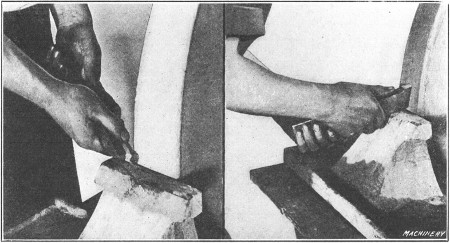

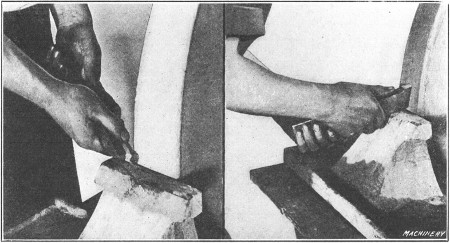

Fig. 14. Grinding the Top and Flank of a Turning Tool

Grinding a Lathe Tool.—The way a turning tool is held

while the top surface is being ground is shown to the left in

Fig. 14. By inclining the tool with the wheel face, it will be

seen that both the back and side slopes may be ground at the

same time. When grinding the flank of the tool it should be

held on the tool-rest of the emery wheel or grindstone, as shown

by the view to the right. In order to form a curved cutting

edge, the tool is turned about the face of the stone while it is

being ground. This rotary movement can be effected by supporting

the inner end of the tool with one hand while the shank

is moved to and fro with the other.

Often a tool which has been ground properly in the first place is

greatly misshapen after it has been sharpened a few times. This is

usually the result of attempts on the part of the workman to re-sharpen

it hurriedly; for example, it is easier to secure a sharp edge on the turning tool shown to the left in Fig. 12, by

grinding the flank as indicated by the dotted line, than by

grinding the entire flank. The clearance is, however, reduced

and the lip angle changed.

There is great danger when grinding a tool of burning it or

drawing the temper from the fine cutting edge, and, aside from

the actual shape of the cutting end, this is the most important

point in connection with tool grinding. If a tool is pressed

hard against an emery or other abrasive wheel, even though the

latter has a copious supply of water, the temper will sometimes

be drawn. When grinding a flat surface, to avoid burning, the

tool should frequently be withdrawn from the stone so that the

cooling water (a copious supply of which should be provided)

can reach the surface being ground. A moderate pressure

should also be applied, as it is better to spend an extra minute

or two in grinding than to ruin the tool by burning, in an attempt

to sharpen it quickly. Of course, what has been said

about burning applies more particularly to carbon steel, but

even self-hardening steels are not improved by being over-heated

at the stone. In some shops, tools are ground to the

theoretically correct shape in special machines instead of by

hand. The sharpened tools are then kept in the tool-room and

are given out as they are needed.

Cutting Speeds and Feeds.—The term cutting speed as applied

to turning operations is the speed in feet per minute of

the surface being turned, or, practically speaking, it is equivalent

to the length of a chip, in feet, which would be turned in

one minute. The term cutting speed should not be confused

with revolutions per minute, because the cutting speed depends

not only upon the speed of the work but also upon its diameter.

The feed of a tool is the amount it moves across the surface

being turned for each revolution; that is, when turning a cylindrical

piece, the feed is the amount that the tool moves sidewise

for each revolution of the work. Evidently the time required

for turning is governed largely by the cutting speed, the feed,

and the depth of the cut; therefore, these elements should be

carefully considered.

Cutting Speeds and Feeds for Turning Tools[1]

| Steel—Standard 7/8-inch Tool |

Cast Iron—Standard 7/8-inch Tool

|

| Depth of Cut in Inches |

Feed in Inches |

Speed in Feet per Minute for a Tool which is to last 11/2

Hour before Re-grinding |

Depth of Cut in Inches |

Feed in Inches |

Speed in Feet per Minute for a Tool which is to last 11/2

Hour before Re-grinding |

Soft

Steel |

Medium

Steel |

Hard

Steel |

Soft

Cast Iron |

Medium

Cast Iron |

Hard

Cast Iron |

| 3/32 |

1/64 |

476 |

|

238 |

|

108 |

|

3/32 |

1/16 |

122 |

|

61 |

.2 |

35 |

.7 |

| 1/32 |

325 |

|

162 |

|

73 |

.8 |

1/8 |

86 |

.4 |

43 |

.2 |

25 |

.2 |

| 1/16 |

222 |

|

111 |

|

50 |

.4 |

3/16 |

70 |

.1 |

35 |

.1 |

20 |

.5 |

| 3/32 |

177 |

|

88 |

.4 |

40 |

.2 |

1/8 |

1/32 |

156 |

|

77 |

.8 |

45 |

.4 |

| 1/8 |

1/64 |

420 |

|

210 |

|

95 |

.5 |

1/16 |

112 |

|

56 |

.2 |

32 |

.8 |

| 1/32 |

286 |

|

143 |

|

65 |

.0 |

1/8 |

79 |

.3 |

39 |

.7 |

23 |

.2 |

| 1/16 |

195 |

|

97 |

.6 |

44 |

.4 |

3/16 |

64 |

.3 |

32 |

.2 |

18 |

.8 |

| 1/8 |

133 |

|

66 |

.4 |

30 |

.2 |

3/16 |

1/32 |

137 |

|

68 |

.6 |

40 |

.1 |

| 3/16 |

1/64 |

352 |

|

176 |

|

80 |

.0 |

1/16 |

99 |

.4 |

49 |

.7 |

29 |

.0 |

| 1/32 |

240 |

|

120 |

|

54 |

.5 |

1/8 |

70 |

.1 |

35 |

.0 |

20 |

.5 |

| 1/16 |

164 |

|

82 |

|

37 |

.3 |

3/16 |

56 |

.8 |

28 |

.4 |

16 |

.6 |

| 1/8 |

112 |

|

56 |

|

25 |

.5 |

1/4 |

1/32 |

126 |

|

62 |

.9 |

36 |

.7 |

| 1/4 |

1/64 |

312 |

|

156 |

|

70 |

.9 |

1/16 |

90 |

.8 |

45 |

.4 |

26 |

.5 |

| 1/32 |

213 |

|

107 |

|

48 |

.4 |

1/8 |

64 |

.1 |

32 |

.0 |

18 |

.7 |

| 1/16 |

145 |

|

72 |

.6 |

33 |

.0 |

3/16 |

52 |

|

26 |

.0 |

15 |

.2 |

| 3/32 |

116 |

|

58 |

.1 |

26 |

.4 |

3/8 |

1/32 |

111 |

|

55 |

.4 |

32 |

.3 |

| 3/8 |

1/64 |

264 |

|

132 |

|

60 |

.0 |

1/16 |

80 |

|

40 |

.0 |

23 |

.4 |

| 1/32 |

180 |

|

90 |

.2 |

41 |

.0 |

1/8 |

56 |

.4 |

28 |

.2 |

16 |

.5 |

| 1/16 |

122 |

|

61 |

.1 |

27 |

.8 |

1/2 |

1/32 |

104 |

|

52 |

.1 |

30 |

.4 |

| 1/2 |

1/64 |

237 |

|

118 |

|

53 |

.8 |

1/16 |

75 |

.2 |

37 |

.6 |

22 |

.0 |

| 1/32 |

162 |

|

80 |

.8 |

36 |

.7 |

1/8 |

43 |

.1 |

21 |

.6 |

12 |

.6 |

| Steel—Standard 5/8-inch Tool |

Cast Iron—Standard 5/8-inch Tool |

| Depth of Cut |

Feed |

Soft

Steel |

Medium

Steel |

Hard

Steel |

Depth of Cut |

Feed |

Soft

Cast Iron |

Medium

Cast Iron |

Hard

Cast Iron |

| 1/16 |

1/64 |

548 |

|

274 |

|

125 |

|

3/32 |

1/32 |

160 |

|

80 |

.0 |

46 |

.6 |

| 1/32 |

358 |

|

179 |

|

81 |

.6 |

1/16 |

110 |

|

55 |

.0 |

32 |

.2 |

| 1/16 |

235 |

|

117 |

|

53 |

.3 |

1/8 |

75 |

.4 |

37 |

.7 |

22 |

.0 |

| 3/32 |

1/64 |

467 |

|

234 |

|

106 |

|

1/8 |

1/32 |

148 |

|

74 |

.0 |

43 |

.3 |

| 1/32 |

306 |

|

153 |

|

69 |

.5 |

1/16 |

104 |

|

51 |

.8 |

32 |

.0 |

| 1/16 |

200 |

|

100 |

|

45 |

.5 |

1/8 |

69 |

.6 |

34 |

.8 |

20 |

.3 |

| 3/32 |

156 |

|

78 |

|

35 |

.5 |

3/16 |

1/64 |

183 |

|

91 |

.6 |

68 |

.0 |

| 1/8 |

1/64 |

417 |

|

209 |

|

94 |

.8 |

1/32 |

135 |

|

67 |

.5 |

39 |

.4 |

| 1/32 |

273 |

|

136 |

|

62 |

.0 |

1/16 |

94 |

|

47 |

.0 |

27 |

.4 |

| 1/16 |

179 |

|

89 |

.3 |

40 |

.6 |

1/8 |

64 |

.3 |

32 |

.2 |

18 |

.8 |

| 3/32 |

140 |

|

69 |

.8 |

31 |

.7 |

1/4 |

1/64 |

171 |

|

85 |

.7 |

50 |

.1 |

| 3/16 |

1/64 |

362 |

|

181 |

|

82 |

.2 |

1/32 |

126 |

|

63 |

.2 |

36 |

.9 |

| 1/32 |

236 |

|

118 |

|

53 |

.8 |

1/16 |

87 |

.8 |

43 |

.9 |

25 |

.6 |

| 1/16 |

155 |

|

77 |

.4 |

35 |

.2 |

3/32 |

70 |

.4 |

35 |

.2 |

20 |

.6 |

| 1/4 |

1/64 |

328 |

|

164 |

|

74 |

.5 |

3/8 |

1/64 |

156 |

|

77 |

.8 |

45 |

.4 |

| 1/32 |

215 |

|

107 |

|

48 |

.8 |

1/32 |

116 |

|

57 |

.8 |

33 |

.8 |

| 3/8 |

1/64 |

286 |

|

143 |

|

65 |

.0 |

1/16 |

79 |

.7 |

39 |

.9 |

23 |

.3 |

Average Cutting Speeds for Turning.—The cutting speed is

governed principally by the hardness of the metal to be turned;

the kind of steel of which the turning tool is made; the shape

of the tool and its heat-treatment; the feed and depth of cut;

whether or not a cooling lubricant is used on the tool; the

power of the lathe and also its construction; hence it is impossible

to give any definite rule for determining either the

speed, feed, or depth of cut, because these must be varied to

suit existing conditions. A general idea of the speeds used in

ordinary machine shop practice may be obtained from the following

figures:

Ordinary machine steel is generally turned at a speed varying

between 45 and 65 feet per minute. For ordinary gray cast

iron, the speed usually varies from 40 to 50 feet per minute;

for annealed tool steel, from 25 to 35 feet per minute; for soft

yellow brass, from 150 to 200 feet per minute; for hard bronze,

from 35 to 80 feet per minute, the speed depending upon the

composition of the alloy. While these speeds correspond

closely to general practice, they can be exceeded for many

machining operations.

The most economical speeds for a given feed and depth of

cut, as determined by the experiments conducted by Mr. F. W.

Taylor, are given in the table, “Cutting Speeds and Feeds for

Turning Tools.” The speeds given in this table represent results

obtained with tools made of a good grade of high-speed

steel properly heat-treated and correctly ground. It will be

noted that the cutting speed is much slower for cast iron than

for steel. Cast iron is cut with less pressure or resistance than

soft steel, but the slower speed required for cast iron is probably

due to the fact that the pressure of the chip is concentrated

closer to the cutting edge, combined with the fact that cast

iron wears the tool faster than steel. The speeds given are

higher than those ordinarily used, and, in many cases, a slower

rate would be necessary to prevent chattering or because of

some other limiting condition.

Factors which limit the Cutting Speed.—It

is the durability of the turning tool or the length of time that it

will turn effectively without grinding, that limits the cutting speed;

and the hardness of the metal being turned combined with the quality of

the tool are the two factors which largely govern the time that a tool

can be used before grinding is necessary. The cutting speed for very

soft steel or cast iron can be three or four times faster than the speed

for hard steel or hard castings, but whether the material is hard or

soft, the kind and quality of the tool used must also be considered, as

the speed for a tool made of ordinary carbon steel will have to be much

slower than for a tool made of modern “high-speed” steel.

When the cutting speed is too high, even though high-speed

steel is used, the point of the tool is softened to such an extent

by the heat resulting from the pressure and friction of the chip,

that the cutting edge is ruined in too short a time. On the

other hand, when the speed is too slow, the heat generated is

so slight as to have little effect and the tool point is dulled by

being slowly worn or ground away by the action of the chip.

While a tool operating at such a low speed can be used a comparatively

long time without re-sharpening, this advantage is

more than offset by the fact that too much time is required for

removing a given amount of metal when the work is revolving

so slowly.

Generally speaking, the speed should be such that a fair

amount of work can be done before the tool requires re-grinding.

Evidently, it would not pay to grind a tool every few

minutes in order to maintain a high cutting speed; neither

would it be economical to use a very slow speed and waste considerable

time in turning, just to save the few minutes required

for grinding. For example, if a number of roughing cuts had

to be taken over a heavy rod or shaft, time might be saved by

running at such a speed that the tool would have to be sharpened

(or be replaced by a tool previously sharpened) when it had

traversed half-way across the work; that is, the time required

for sharpening or changing the tool would be short as compared

with the gain effected by the higher work speed. On the

other hand, it might be more economical to run a little slower

and take a continuous cut across the work with one tool.

The experiments of Mr. Taylor led to the conclusion that, as

a rule, it is not economical to use roughing tools at a speed so

slow as to cause them to last more than 11/2 hour without being

re-ground; hence the speeds given in the table previously referred

to are based upon this length of time between grindings.

Sometimes the work speed cannot be as high as the tool will

permit, because of the chattering that often results when the

lathe is old and not massive enough to absorb the vibrations, or

when there is unnecessary play in the working parts. The shape

of the tool used also affects the work speed, and as there are so

many things to be considered, the proper cutting speed is best

determined by experiment.

Rules for Calculating Cutting Speeds.—The number of revolutions

required to give any desired cutting speed can be found

by multiplying the cutting speed, in feet per minute, by 12 and

dividing the product by the circumference of the work in inches.

Expressing this as a formula we have

in which

For example if a cutting speed of 60 feet per minute is wanted

and the diameter of the work is 5 inches, the required speed

would be found as follows:

If the diameter is simply multiplied by 3 and the fractional

part is omitted, the calculation can easily be made, and the result

will be close enough for practical purposes. In case the cutting

speed, for a given number of revolutions and diameter, is wanted,

the following formula can be used:

Machinists who operate lathes do not know, ordinarily, what

cutting speeds, in feet per minute, are used for different classes

of work, but are guided entirely by past experience.

Feed of Tool and Depth of Cut.—The amount of feed and

depth of cut also vary like the cutting speed, for different conditions.

When turning soft machine steel the feed under

ordinary conditions would vary between 1/32 and 1/16 inch per

revolution. For turning soft cast iron the feed might be increased

to from 1/16 to 1/8 inch per revolution. These feeds

apply to fairly deep roughing cuts. Coarser feeds might be

used in many cases especially when turning large rigid parts in

a powerful lathe. The depth of a roughing cut in machine

steel might vary from 1/8 to 3/8 inch, and in cast iron from 3/16 to

1/2 inch. These figures are intended simply to give the reader a

general idea of feeds and cuts that are feasible under average

conditions.

Ordinarily coarser feeds and a greater depth of cut can be

used for cast iron than for soft steel, because cast iron offers

less resistance to turning, but in any case, with a given depth of

cut, metal can be removed more quickly by using a coarse feed

and the necessary slower speed, than by using a fine feed and

the higher speed which is possible when the feed is reduced.

When the turning operation is simply to remove metal, the feed

should be coarse, and the cut as deep as practicable. Sometimes

the cut must be comparatively light, either because the

work is too fragile and springy to withstand the strain of a

heavy cut, or the lathe has not sufficient pulling power. The

difficulty with light slender work is that a heavy cut may cause

the part being turned to bend under the strain, thus causing the

tool to gouge in, which would probably result in spoiling the

work. Steadyrests can often be used to prevent flexible parts

from springing, as previously explained, but there are many

kinds of light work to which the steadyrest cannot be applied

to advantage.

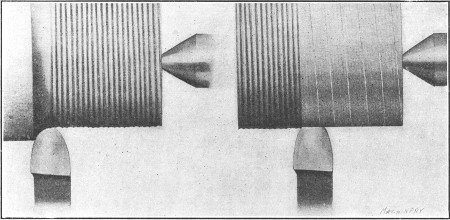

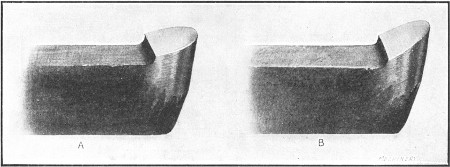

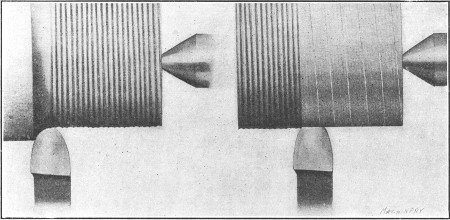

Fig. 15. Roughing Cut—Light Finishing Cut and Coarse Feed

The amount of feed to use for a finishing cut might, properly, be

either fine or coarse. Ordinarily, fine feeds are used for finishing

steel, especially if the work is at all flexible, whereas finishing cuts

in cast iron are often accompanied by a coarse feed. Fig. 15 illustrates the feeds that are often used when turning

cast iron. The view to the left shows a deep roughing cut and

the one to the right, a finishing cut. By using a broad flat

cutting edge set parallel to the tool's travel, and a coarse feed

for finishing, a smooth cut can be taken in a comparatively

short time. Castings which are close to the finished size in

the rough can often be finished to advantage by taking a single

cut with a broad tool, provided the work is sufficiently rigid.

It is not always practicable to use these broad tools and coarse

feeds, as they sometimes cause chattering, and when used on

steel, a broad tool tends to gouge or “dig in” unless the part

being turned is rigid. Heavy steel parts, however, are sometimes

finished in this way. The modern method of finishing

many steel parts is to simply rough them out in a lathe to

within, say, 1/32 inch of the required diameter and take the finishing

cut in a cylindrical grinding machine.

Effect of Lubricant on Cutting Speed.—When

turning iron or steel a higher cutting speed can be used, if a stream

of soda water or other cooling lubricant falls upon the chip at the

point where it is being removed by the tool. In fact, experiments have

shown that the cutting speed, when using a large stream of cooling water

and a high-speed steel tool, can be about 40 percent higher than when

turning dry or without a cooling lubricant. For ordinary carbon steel

tools, the gain was about 25 per cent. The most satisfactory results

were obtained from a stream falling at a rather slow velocity but in

large volume. The gain in cutting speed, by the use of soda water or

other suitable fluids, was found to be practically the same for all

qualities of steel from the softest to the hardest.

Cast iron is usually turned dry or without a cutting lubricant.

Experiments, however, made to determine the effect of applying

a heavy stream of cooling water to a tool turning cast iron,

showed the following results: Cutting speed without water, 47

feet per minute; cutting speed with a heavy stream of water,

nearly 54 feet per minute; increase in speed, 15 per cent. The

dirt caused by mixing the fine cast-iron turnings with a cutting

lubricant is an objectionable feature which, in the opinion of

many, more than offsets the increase in cutting speed that

might be obtained.

Turret lathes and automatic turning machines are equipped

with a pump and piping for supplying cooling lubricant to the

tools in a continuous stream. Engine lathes used for general

work, however, are rarely provided with such equipment and

a lubricant, when used, is often supplied by a can mounted at

the rear of the carriage, having a spout which extends above the

tool. Owing to the inconvenience in using a lubricant on an

engine lathe, steel, as well as cast iron, is often turned dry

especially when the work is small and the cuts light and comparatively

short.

Lubricants Used for Turning.—A

good grade of lard oil is an excellent lubricant for use when turning

steel or wrought iron and it is extensively used on automatic screw

machines, especially those which operate on comparatively small work.

For some classes of work, especially when high-cutting speeds are used,

lard oil is not as satisfactory as soda water or some of the commercial

lubricants, because the oil is more sluggish and does not penetrate to

the cutting point with sufficient rapidity. Many lubricants which are

cheaper than oil are extensively used on “automatics” for general

machining operations. These usually consist of a mixture of sal-soda

(carbonate of soda) and water, to which is added some ingredient such as

lard oil or soft soap to thicken or give body to the lubricant.

A cheap lubricant for turning, milling, etc., and one that has

been extensively used, is made in the following proportions:

1 pound of sal-soda, 1 quart of lard oil, 1 quart of soft soap,

and enough water to make 10 or 12 gallons. This mixture is

boiled for one-half hour, preferably by passing a steam coil

through it. If the solution should have an objectionable odor,

this can be eliminated by adding 2 pounds of unslaked lime. The

soap and soda in this solution improve the lubricating quality

and also prevent the surfaces from rusting. For turning and

threading operations, plain milling, deep-hole drilling, etc., a

mixture of equal parts of lard oil and paraffin oil will be found

very satisfactory, the paraffin being added to lessen the expense.

Brass or bronze is usually machined dry, although lard oil is

sometimes used for automatic screw machine work. Babbitt

metal is also worked dry, ordinarily, although kerosene or

turpentine is sometimes used when boring or reaming. If

babbitt is bored dry, balls of metal tend to form on the tool

point and score the work. Milk is generally considered the best

lubricant for machining copper. A mixture of lard oil and

turpentine is also used for copper. For aluminum, the following

lubricants can be used: Kerosene, a mixture of kerosene

and gasoline, soap-water, or “aqualine” one part, water 20

parts.

Lard Oil as a Cutting Lubricant.—After

being used for a considerable time, lard oil seems to lose some of its

good qualities as a cooling compound. There are several reasons for

this: Some manufacturers use the same oil over and over again on

different materials, such as brass, steel, etc. This is objectionable,

for when lard oil has been used on brass it is practically impossible to

get the fine dust separated from it in a centrifugal separator. When

this impure oil is used on steel, especially where high-speed steels are

employed, it does not give satisfactory results, owing to the fact that

when the cutting tool becomes dull, the small brass particles “freeze”

to the cutting tool and thus produce rough work. The best results are

obtained from lard oil by keeping it thin, and by using it on the same

materials—that is, not transferring the oil from a machine in which

brass is being cut to one where it would be employed on steel. If the

oil is always used on the same class of material, it will not lose any

of its good qualities.

Prime lard oil is nearly colorless, having a pale yellow or

greenish tinge. The solidifying point and other characteristics

of the oil depend upon the temperature at which it was expressed,

winter-pressed lard oil containing less solid constituents of the

lard than that expressed in warm weather. The specific gravity

should not exceed 0.916; it is sometimes increased by adulterants,

such as cotton-seed and maize oils.

Return to Contents